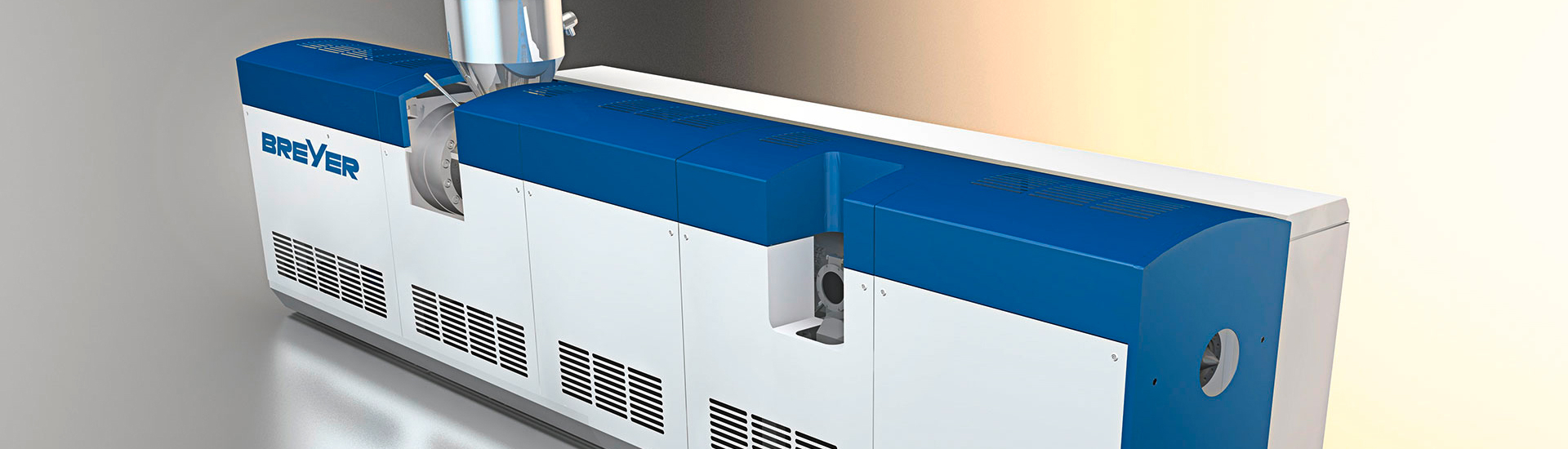

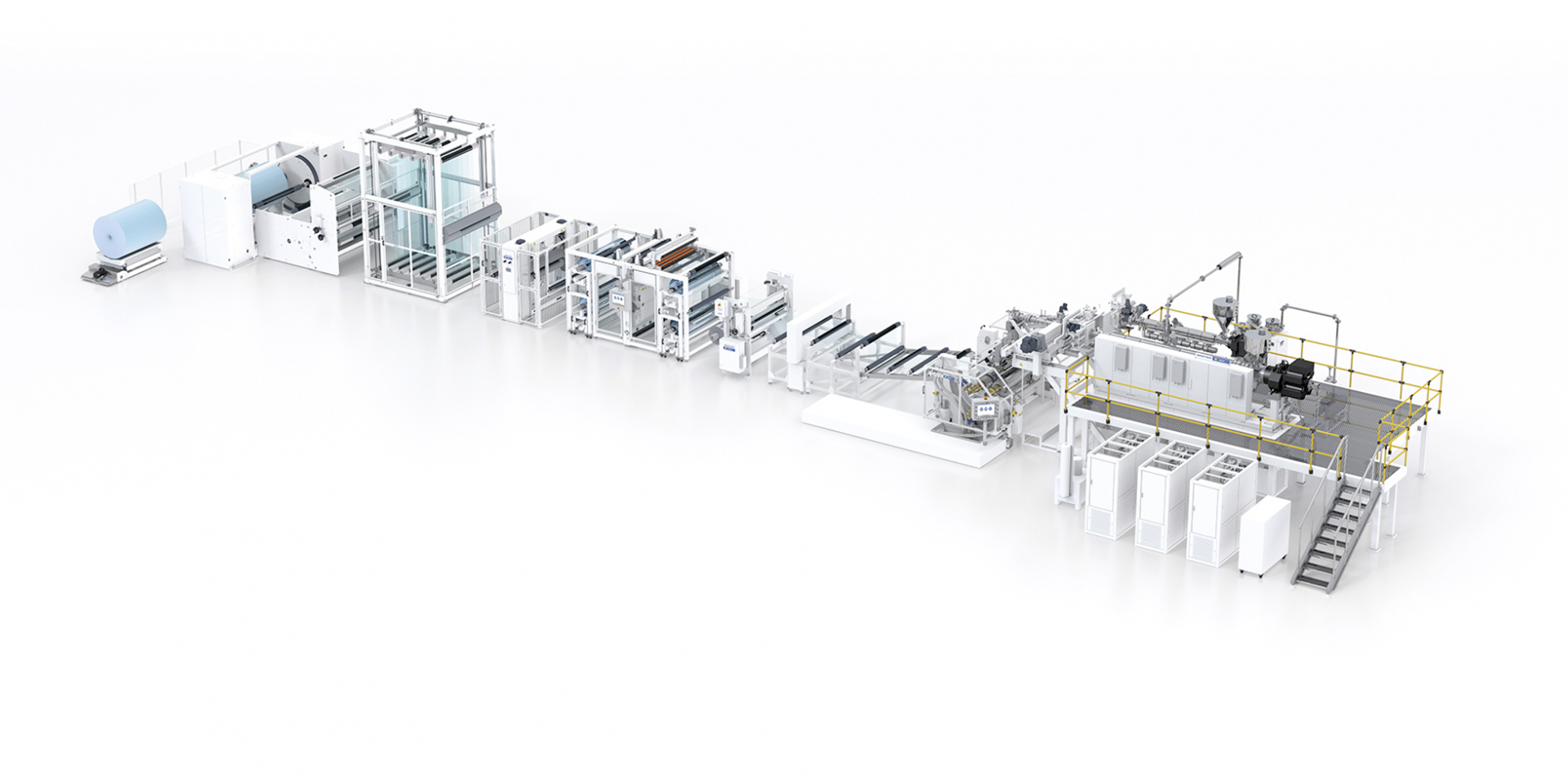

BREYER OptiFlex

Extrusion line for optical film

With our technology you get security.

The manufacturing of a film is nothing special. However, the creation of a high quality polished flat film of minimal thickness is a different matter altogether.

You have the choice. And every possibility.

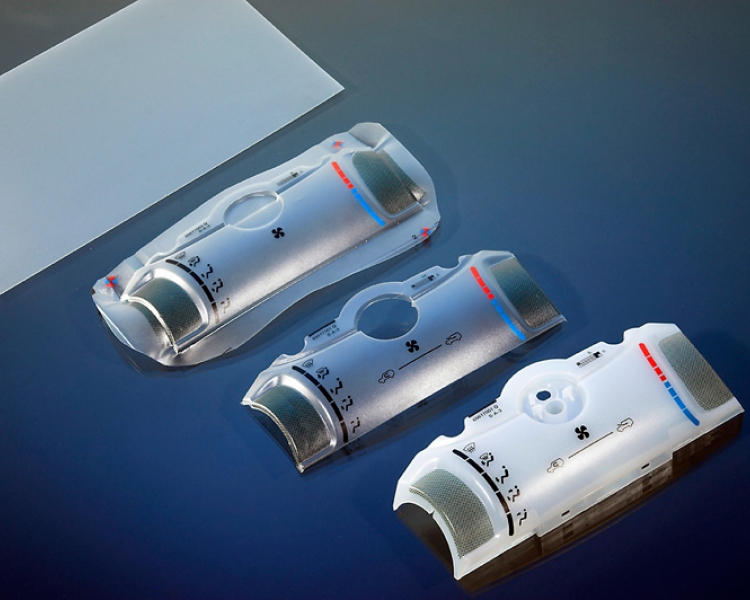

With the BREYER OptiFlex line you are staying always flexible. Both side polished, mat and structured film with optical properties can be produced.

The production of ultra-thin, low-tension films of high optical quality in particular, is quickly separating the men from the boys. We can boast an unbeatable combination of superior know-how, gained over many years and excellent extrusion technology.

Thanks to our special calender techniques, tensions in these films can be kept to a minimum.

The particularly precise, reproducible adjustment of the roll gap combined with the high stability of the calender rolls is an essential prerequisite for the successful production of minimum film thicknesses.

It is not without reason that people rely on BREYER technology time and time again. And of this, we are more than a little proud.

Application

- LCD- und TV-monitors

- IMD, IML films

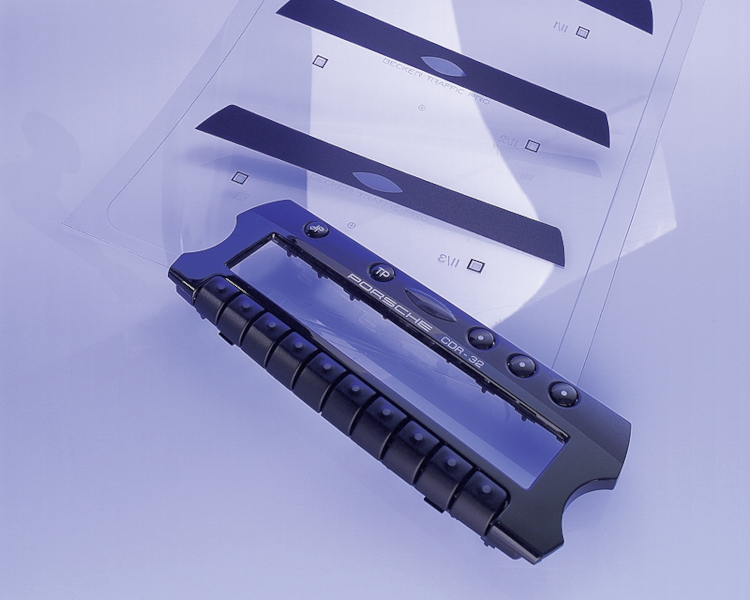

- Passport and credit cards

- Mobilphones

- Instrument panels

- Dekor film

- Ski und snowboards

Advantages

- Energy saving and powerful single screw extruders

- Processing without predrying

- Quick start up by our patented meltpump control

- Automatic controled dies

- Calenders with precision gap adjustment (distcance and pressure controlled), automatic film thickness change

- Polished, mat and structured as well as cast film can be produce with the same machine

- Solid roll design in highest quality for lowest tolerances

- Easy and rapid adjustment of film flatness

Technical data

| Film thickness, polished | 0,08 – 2,0 mm |

| Film width | 750 – 2000 mm |

| Performance | 300 – 700 kg/h |

| Material | PC, PMMA, PET, PES, COC, ETFE, EVA, etc. |

| Versions | Mono und coextruded, polished, mat, struktured |

Examples of application