BREYER Energy Management and Noise Reduction

Intelligent energy management for tube extrusion lines – energy savings of up to 25 %. BREYER now offers different energy saving modules for tube extrusion lines such as:

Energy Saving Module 3

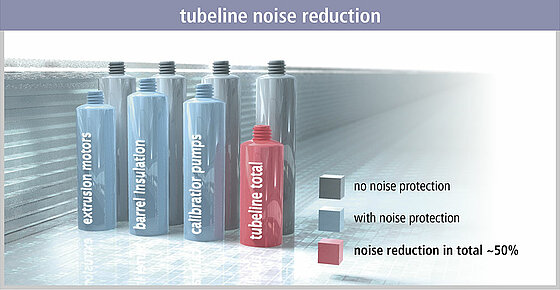

Noise reduction of the complete line of up to 50%!

By using the different modules BREYER achieves a noise reduction for the complete tube line by 11 dB (A) on average. This corresponds to a reduction of approx. 50% of the complete noise level compared to a tube line without noise protection.

This reduction is achieved due to the use of:

- torque motors (direct drives, water cooled > see also module 1

- encapsulation on the calibrator and on extruder > see also module 2

- special vacuum pumps

Energy Saving Module 4

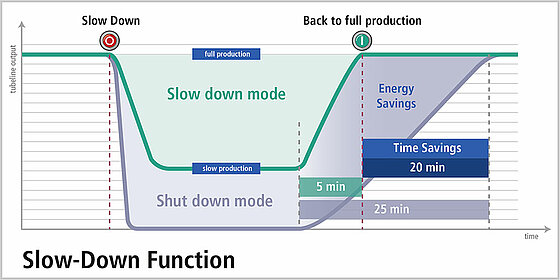

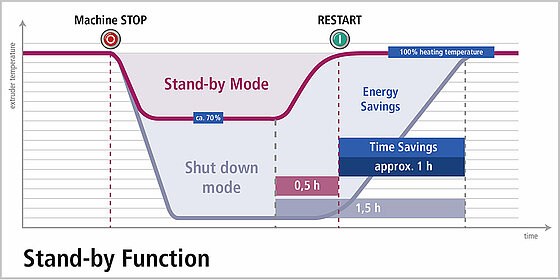

Slow down function and Standby function

- Slow down: minimisation of output capacity (in case of production problems on downstream)

- Slow down: automatic or manual restart of the line from low to high production level

- Slow down: production level in slow down mode variably adjustable

- Standby: reduction of heating temperature variably adjustable, therefore short restart time

- Slow down / Standby: easy to operate by pushing the button on the display

Advantages

- Reduction of overproduction and energy-saving in case of disfunction on downstream lines (header, printer, etc.)

- Coordinated release of the heat and drive capacities, enabling reduction of the installed power capacity as well as current peaks