Precision tools for exceptional products

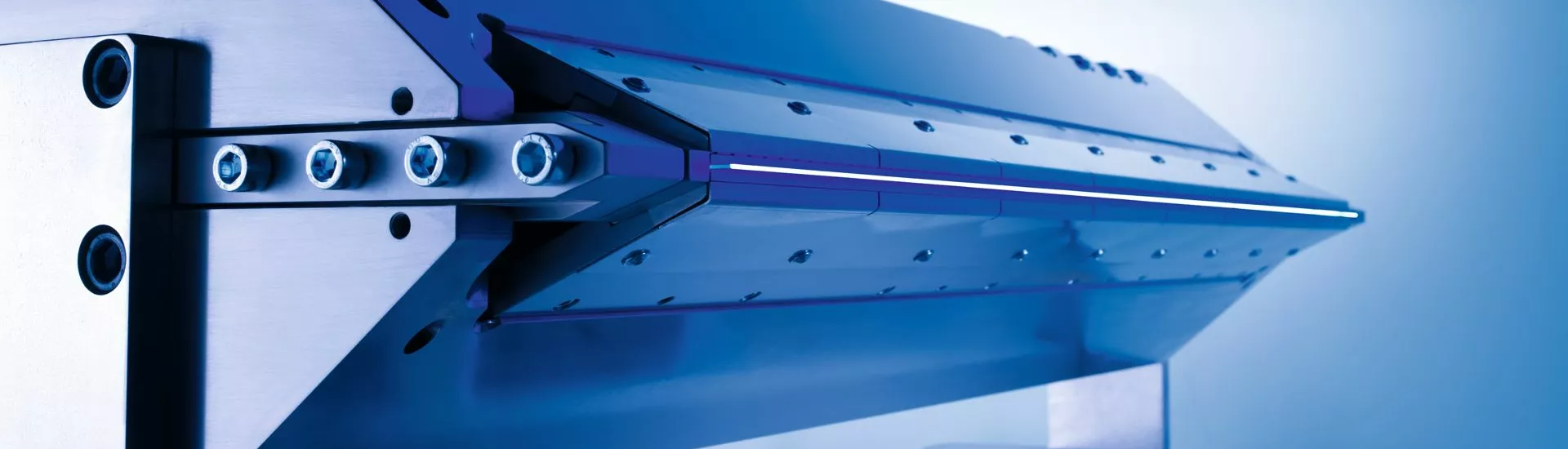

BREYER flat sheet dies are developed with state-of-the-art software, built in 3D design, and manufactured on CNC machines. They get their high-quality finish through the selection of materials and coating depending on the application, combined with a professional polish. Decades of experience and control of the complete extrusion process enable this perfection.

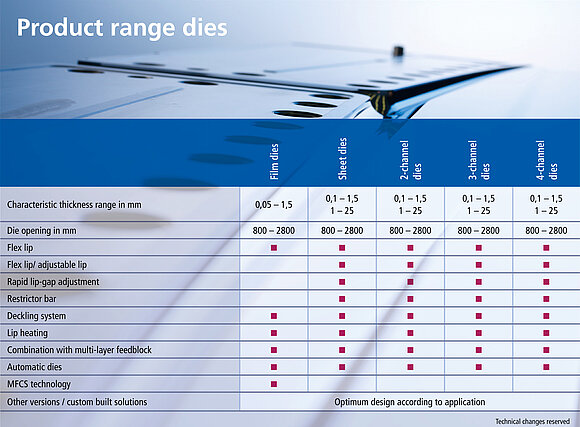

Delivery program

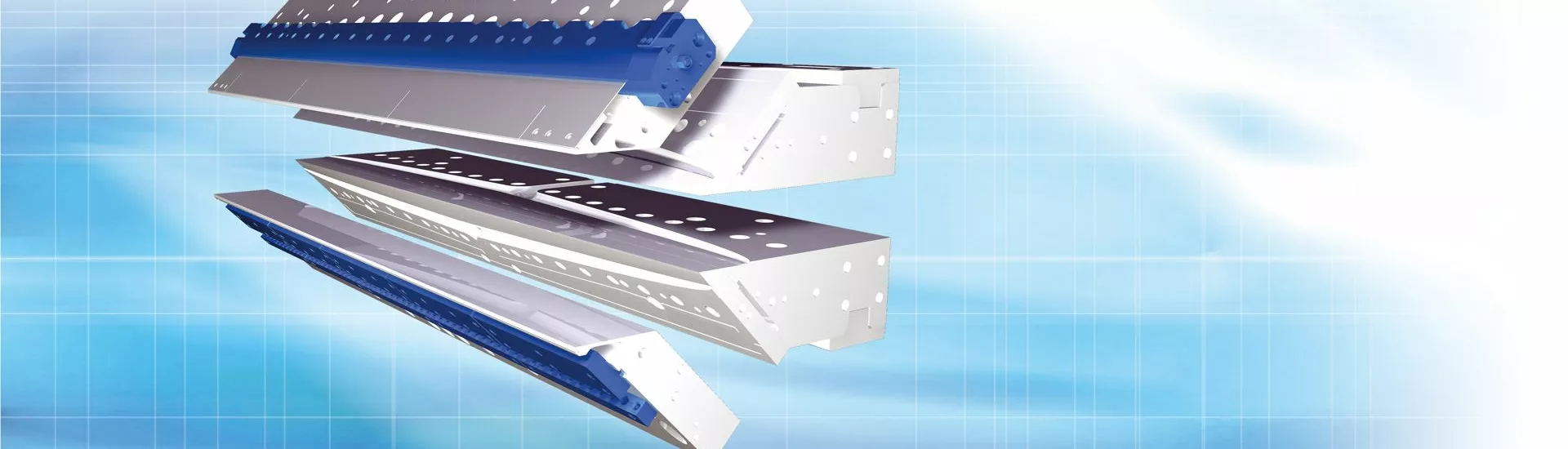

The program includes single layer and multi-layer dies, with widths of up to 2800 mm. The dies are used for manufacturing flat films (typical thickness range of 0.05 - 1.5 mm) and also for sheet production (thickness of 1 - 25 mm).

All common thermoplastics as well as so-called engineering plastics can be processed. BREYER dies are used in BREYER extrusion lines but also in systems from other manufacturers.

BREYER film and sheet dies are available with the following additional equipment:

- Rapid lip gap adjustment

- optimised die shape

- Restrictor bar

- Deckling systems

- Collision protection

- Thickness measuring systems

- Control system

- Die suspension

- Die carriage

Direct contact to business unit