Calender for flat film

Changing film thickness by push of the button

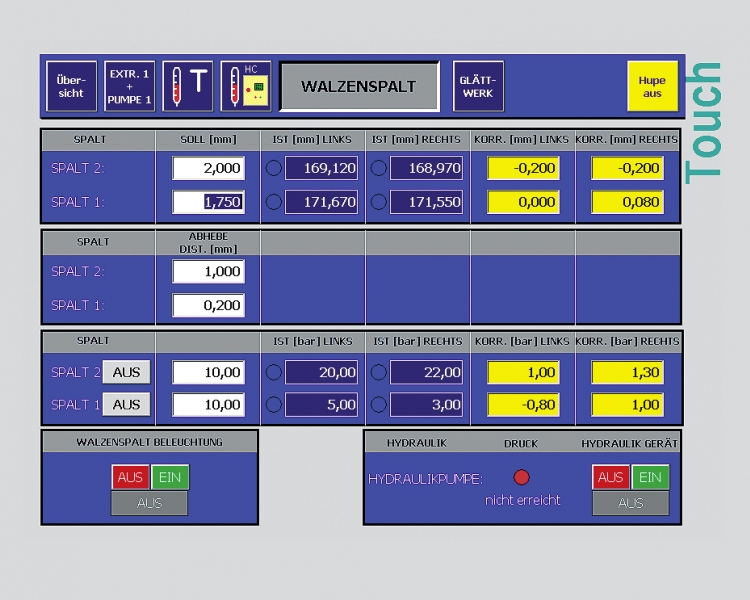

The BREYER calender gap adjustment "fast & easy" does not involve any mechanical adjusting parts. A sophisticated system permits precise and accurate positioning.

Amazingly, this precision is achieved during production and at full load.

Rapidness, precision and comfort in one

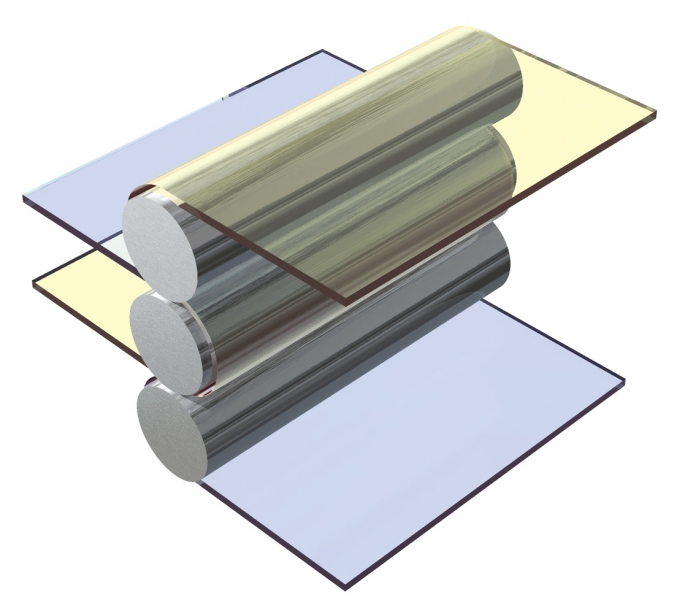

In the past, mechanisms were built into the calenders which allowed a more or less precise setting for film and sheet thickness. From a simple adjusting screws and handwheel adjustment right through to a motorized adjustment method, which adjusted the gap between two rolls, all kinds of mechanism were available. By these methods the film/sheet thickness was adjusted in the calender.

Maximum of flexibility

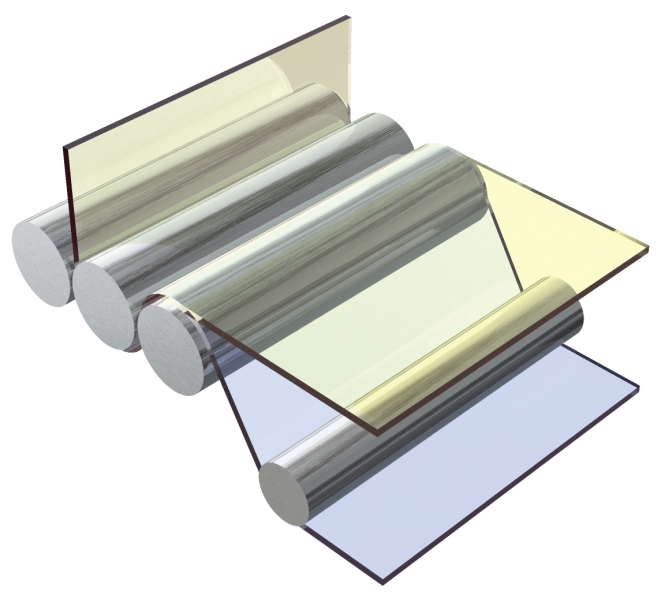

BREYER calenders for film extrusion offers a maximum of flexiblility for your production. Thanks of the fast roll exchange device roll change is not anymore a matter of hours.

Simple, just by push of the button

The setpoints are entered via a color touch screen. The gap changes then immediately at a touch of a button.Furthermore: The meltbank may be passed via a pre-adjustable lift-off gap, again at the touch of a button. To achieve this, the rolls are opened for a few tenths of a second, so that the meltbank can be passed through. Immediately afterwards the gap is closed again, by pressing a button, and the original gap is restored, without the operator having to “re-adjust” it.

Distance adjustment or pressure control

The unique BREYER gap adjustment system is rendering real benefits to the customer when it comes to film extrusion:

this system includes an automatic film thickness setting (0.1 – 1mm): The operation mode allows a precise and automatic adjustment of the gap, simply by changing the extrusion speed. The operator changes the speed value on the touch screen in accordance with the new product thickness, and within a matter of seconds the product is set to the desired thickness. This is a clear advantage in terms of time and costs compared with conventional gap adjustment systems, which require the operator to adjust the speed separately, after the gap adjustments have been implemented.

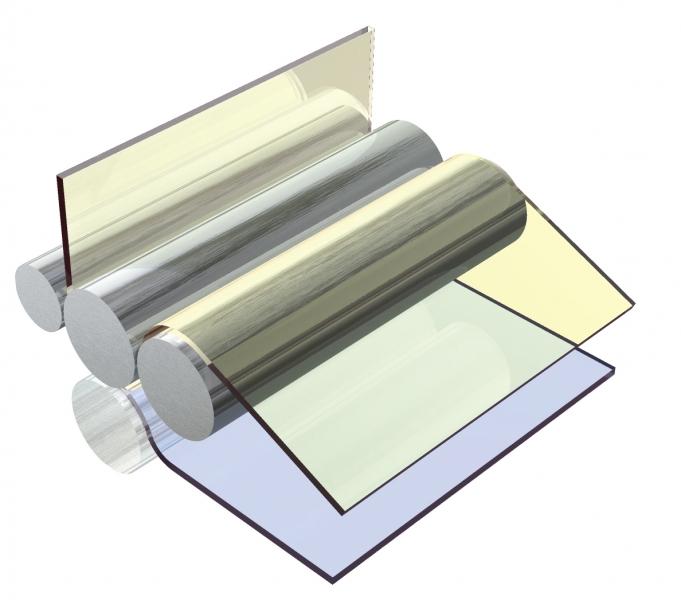

High optical quality

Using the modus "pressure control" first class quality film can be produced with lower tensions, resp lower retardation rates.

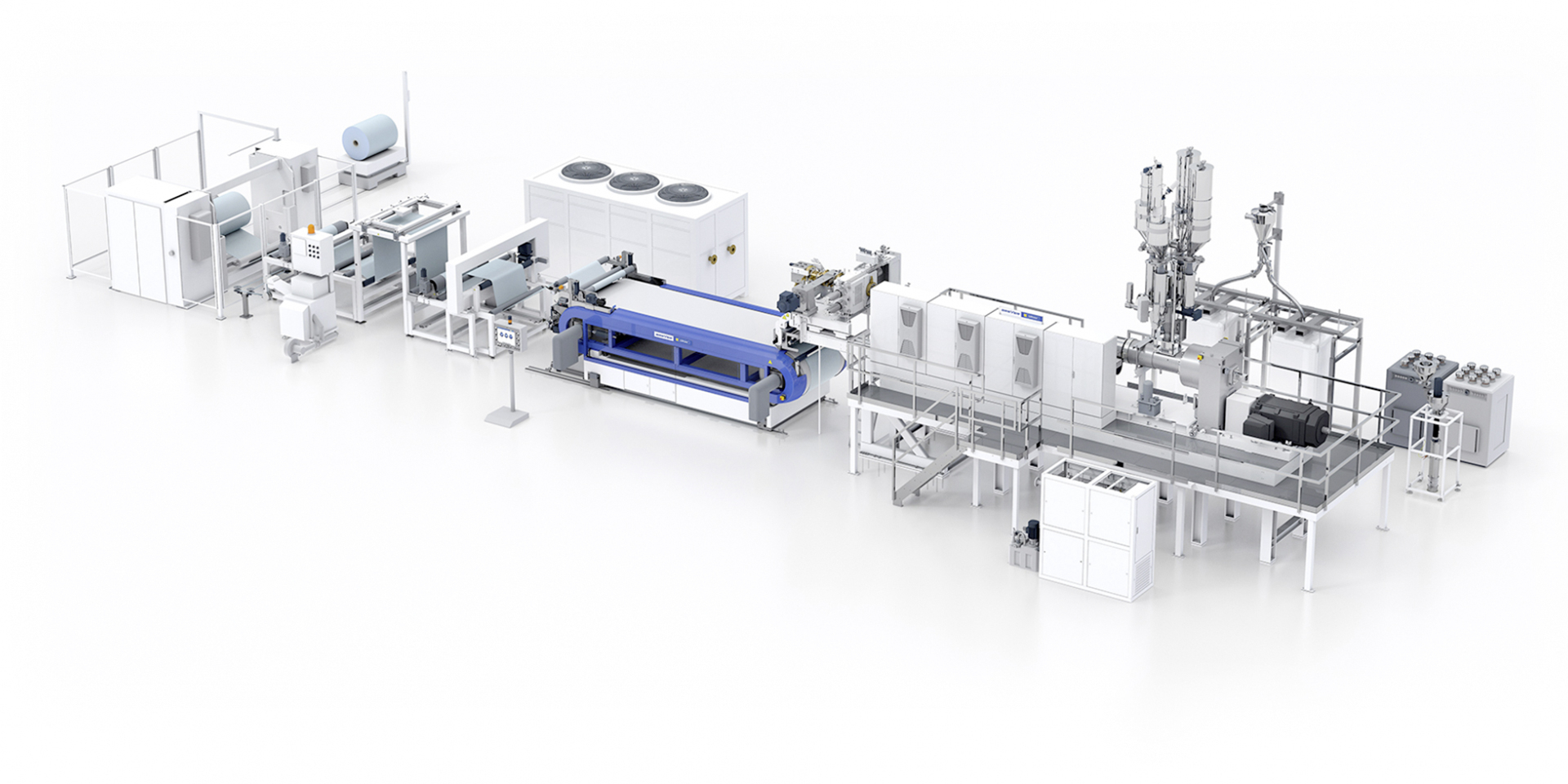

BREYER CellProtect

Extrusion line for EVA and POE solar film

The convincing extrusion technology for the production of low shrinkage solar encapsulant film for PV-modules. BREYER offers the complete line including proofed recipe and service.

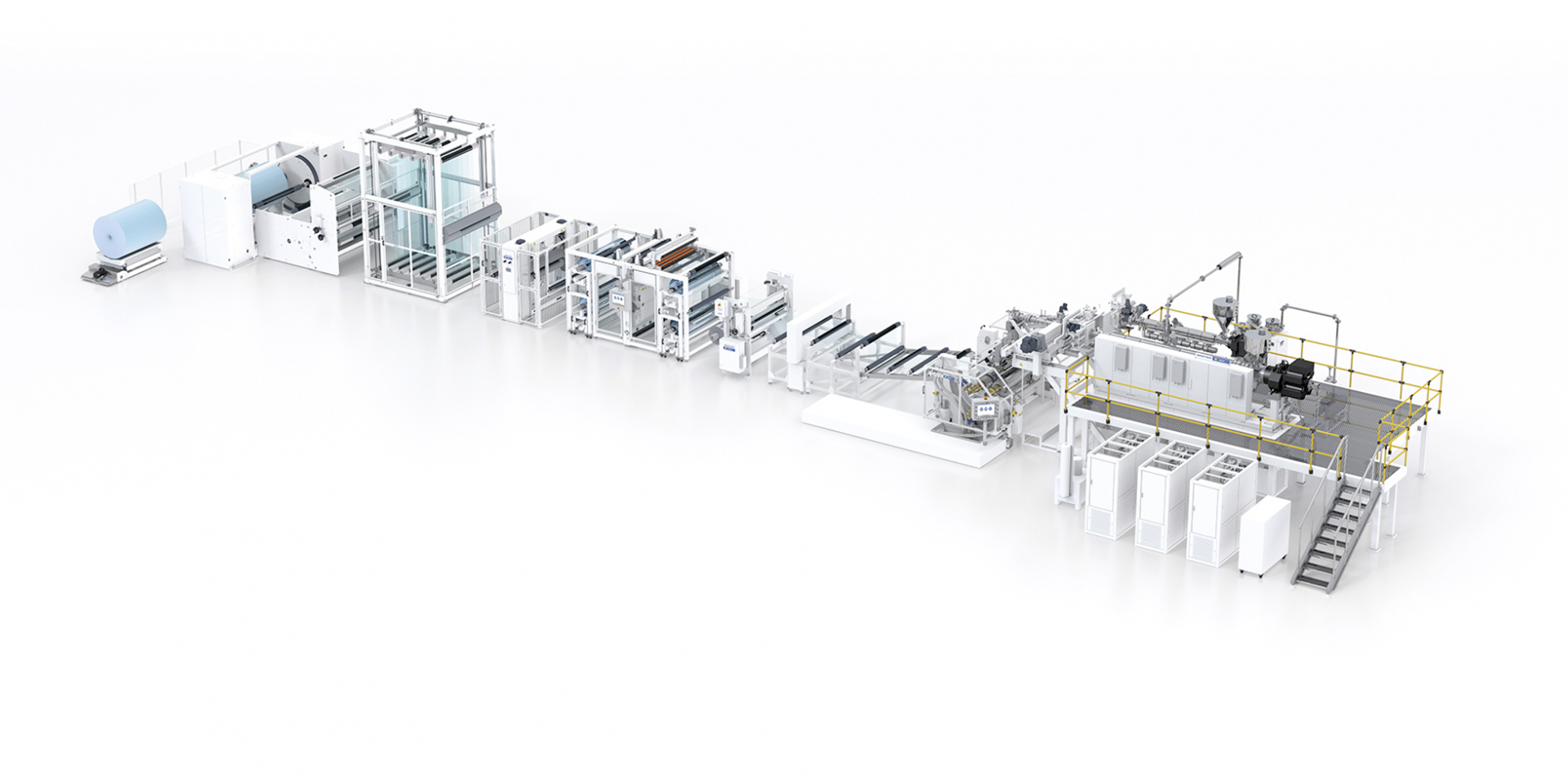

BREYER OptiFlex

Extrusion line for optical film

The manufacturing of a film is nothing special. However, the

creation of a high quality polished flat film of minimal thickness is a different matter altogether.

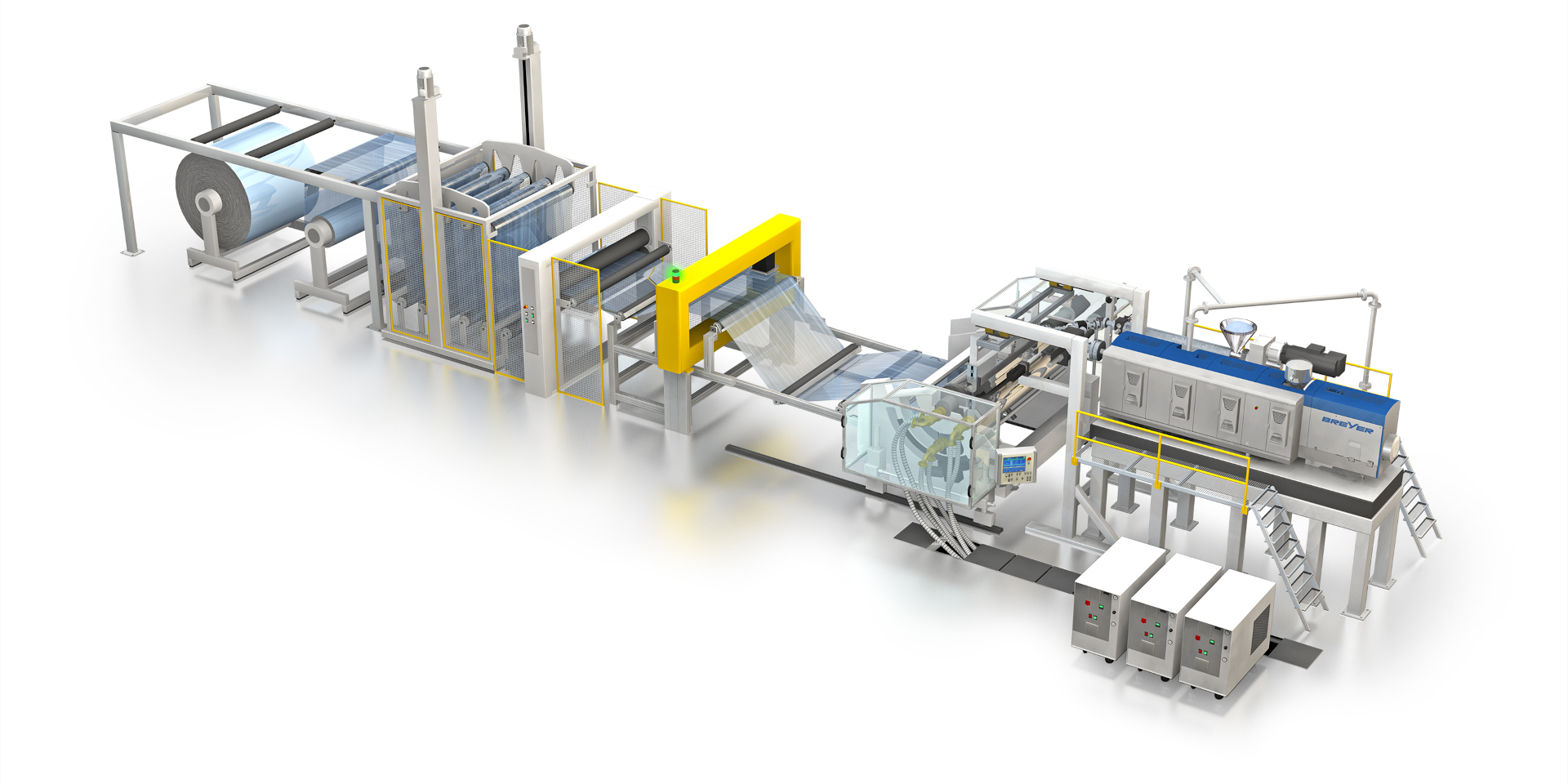

BREYER ThermoFlex Extrusion line for thermoforming film

It is helpful to differentiate yourself with special characteristics especially in a difficult market environment. Better quality always pays off.