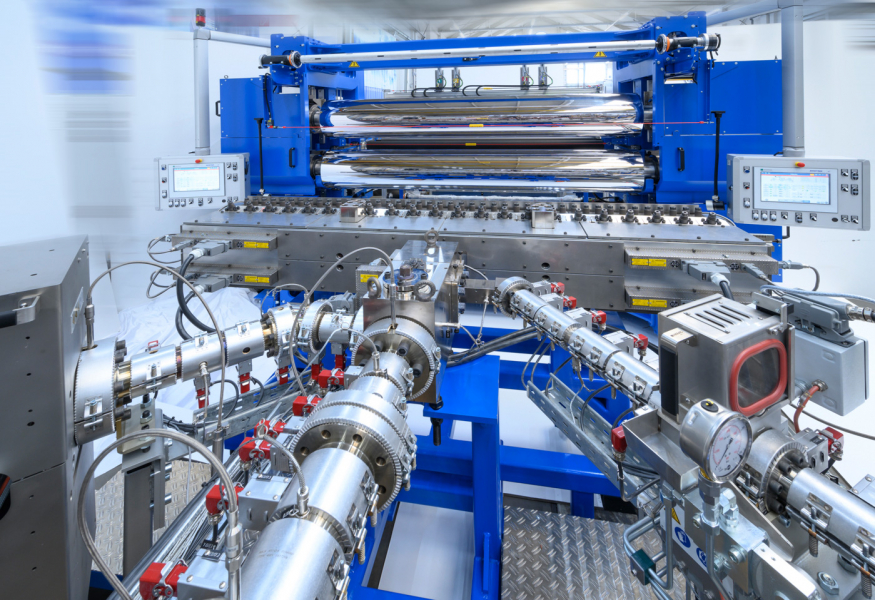

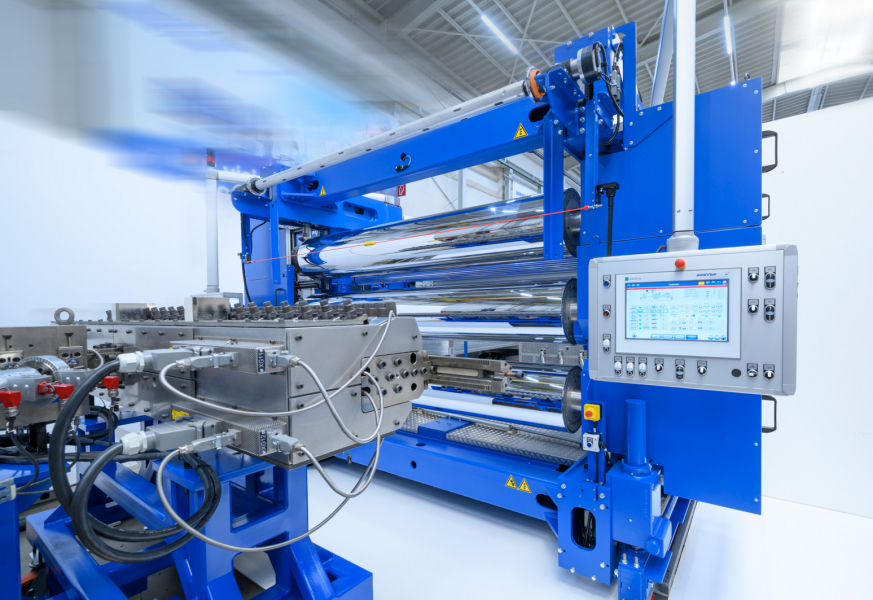

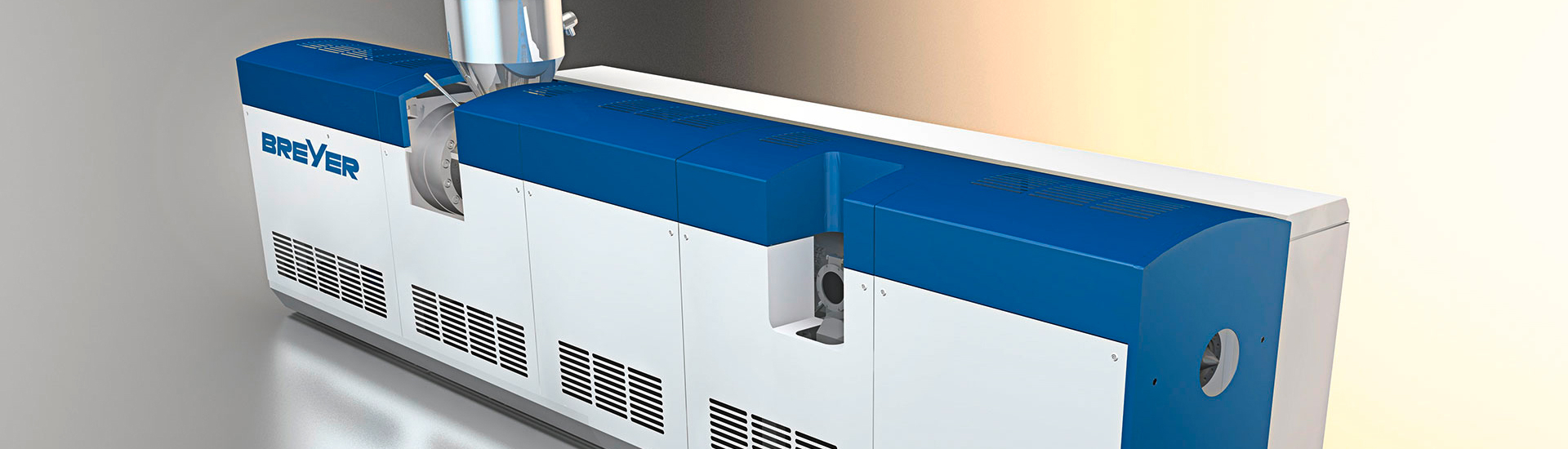

BREYER SolidStar

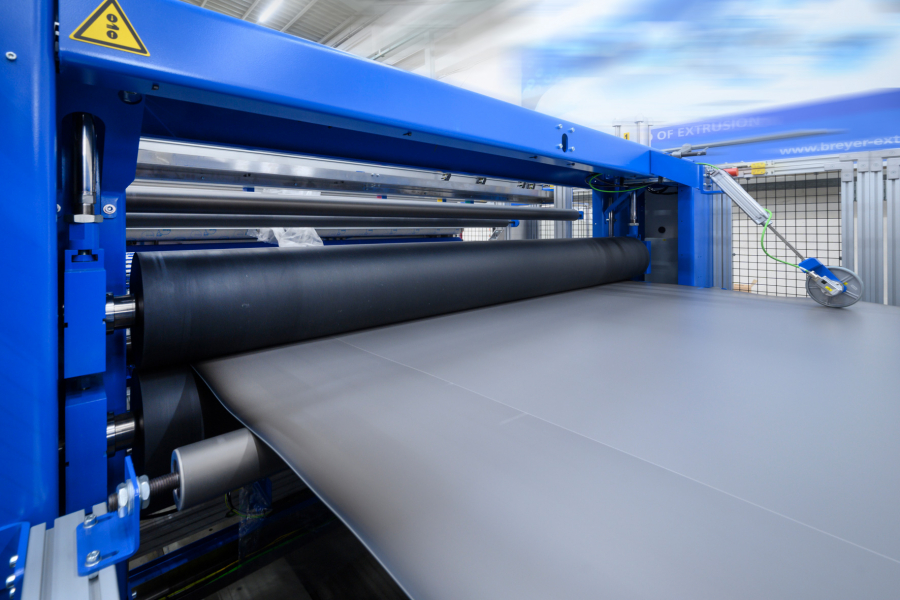

Extrusion lines for technical sheet

Standing still is falling behind.

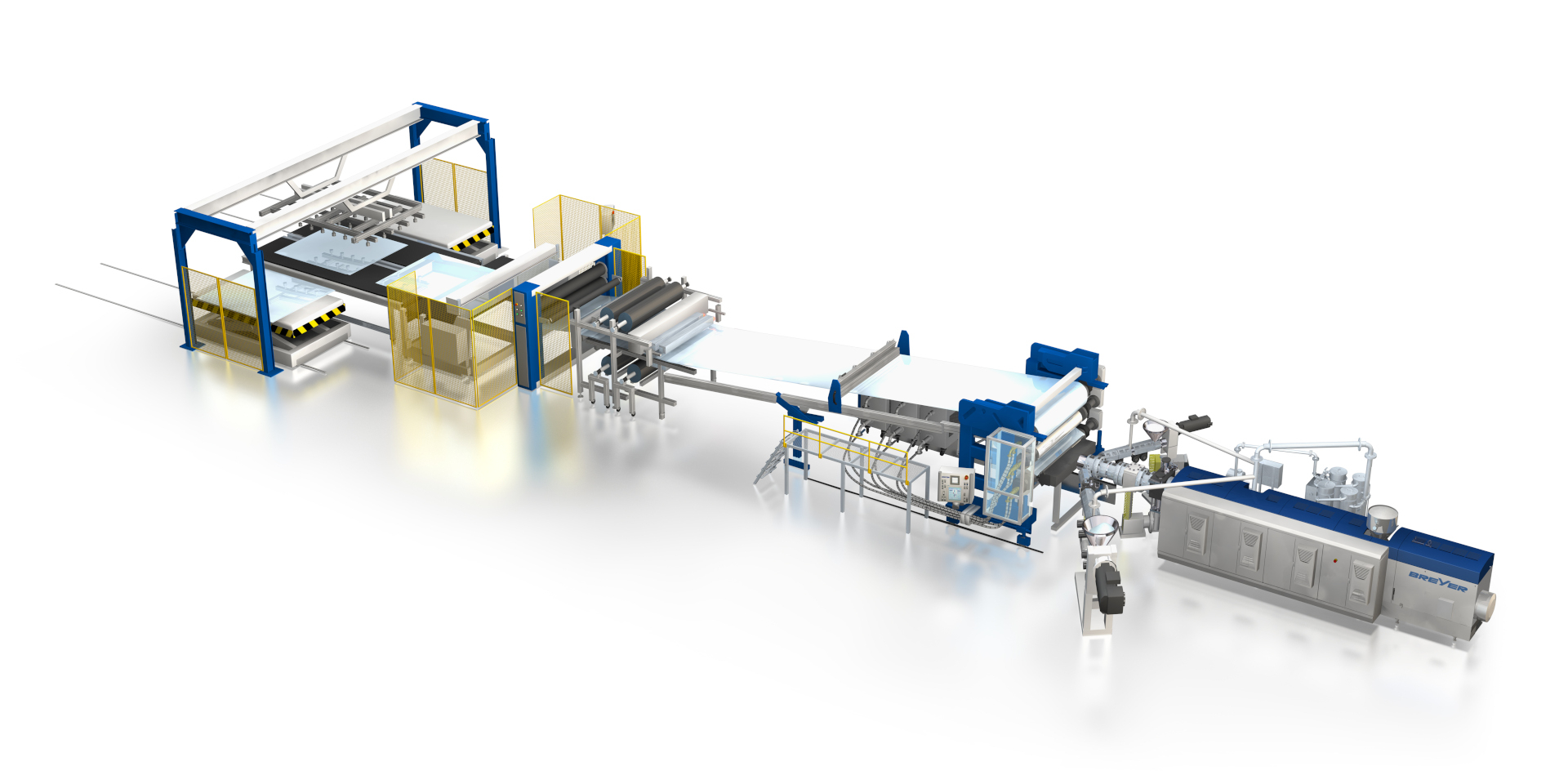

There is hardly any other industry demanding higher flexibility in production than the automobile and consumer goods industry. Speed and a high level of adaptability are therefore vital for efficient production even in the case of small lots.

The solid and sophisticated BREYER system components offer you all the possibilities. This means that you always remain flexible enough to produce for a series of other applications, which the market demands.

The efficiency

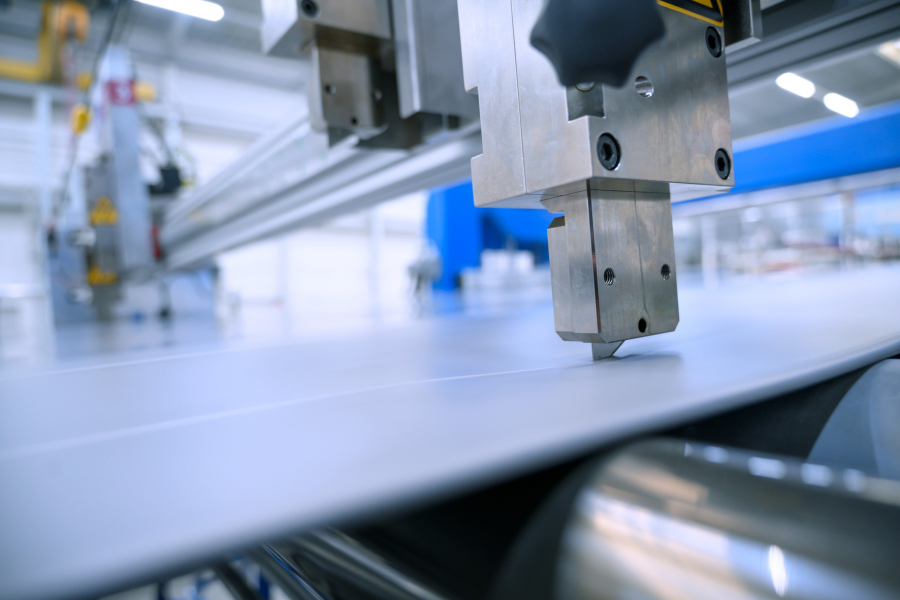

of the extrusion line is essentially determined by an optimized use of materials. High availability, low tolerances, minimum scrap and high throughput performance therefore are the standards by which our systems are conceived.

Advantages

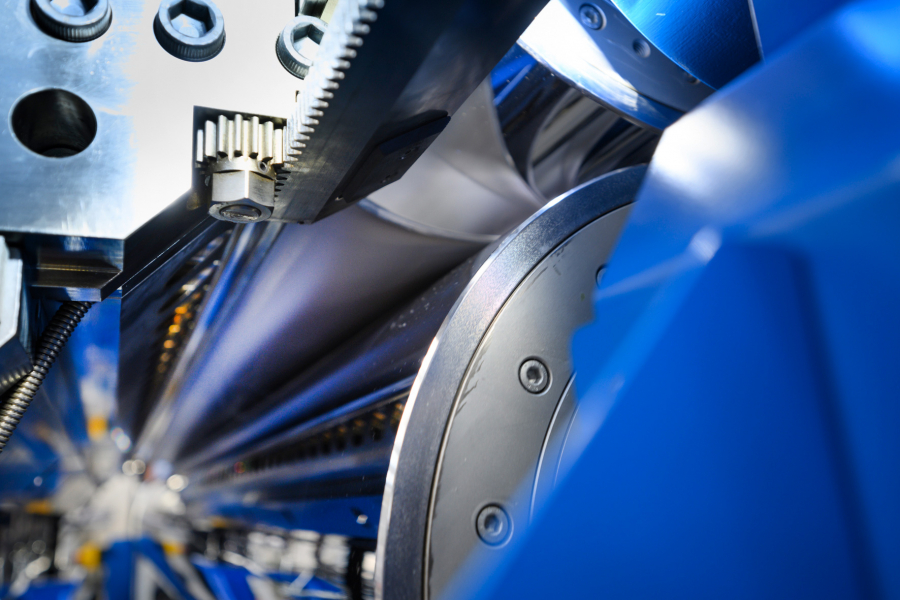

- flexible machine configuration

- High output

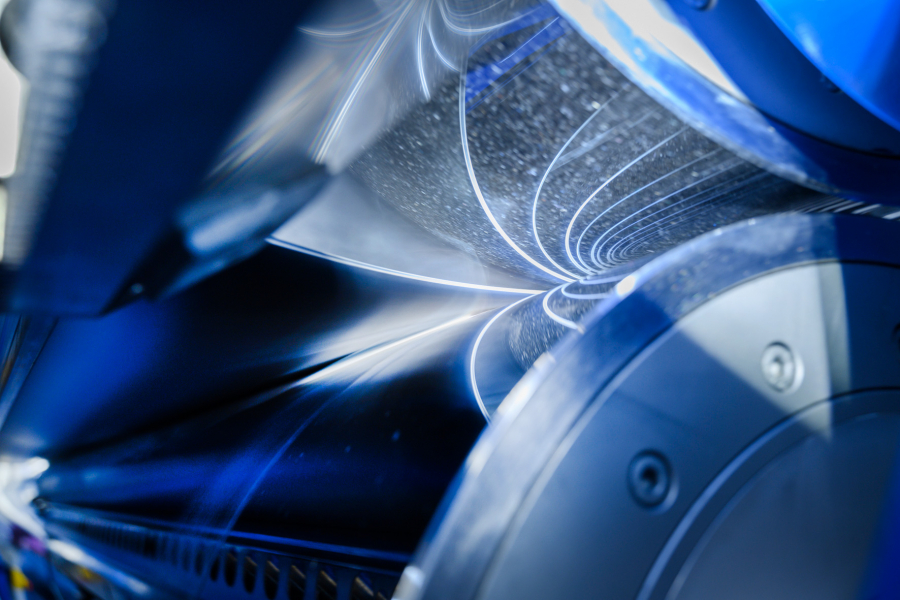

- Effective venting - extrusion without drying

- Coextrusion by feedblock or/and multilayer dies

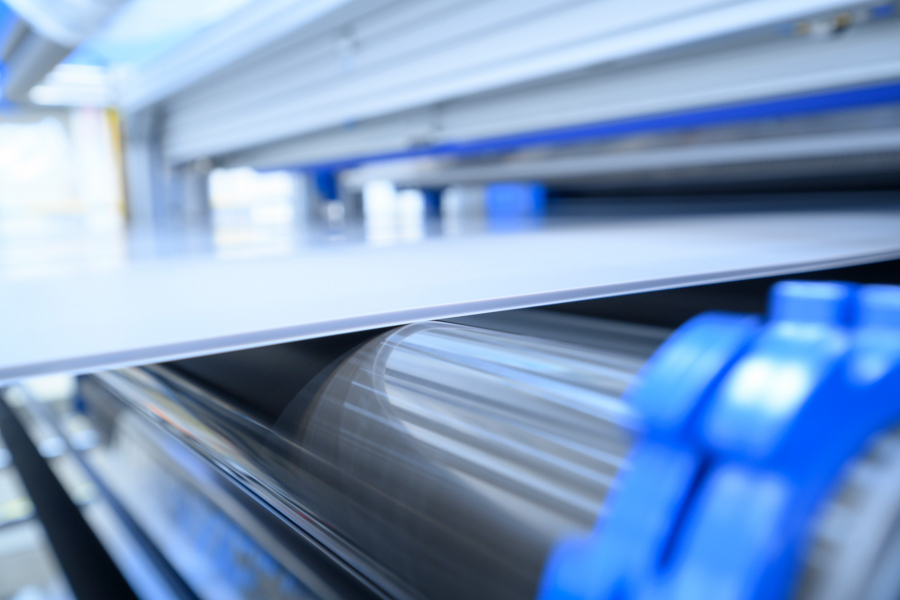

- Polishing unit with fast roll changing device

- smooth, embossed, decorated sheets from a single machine

Technical data

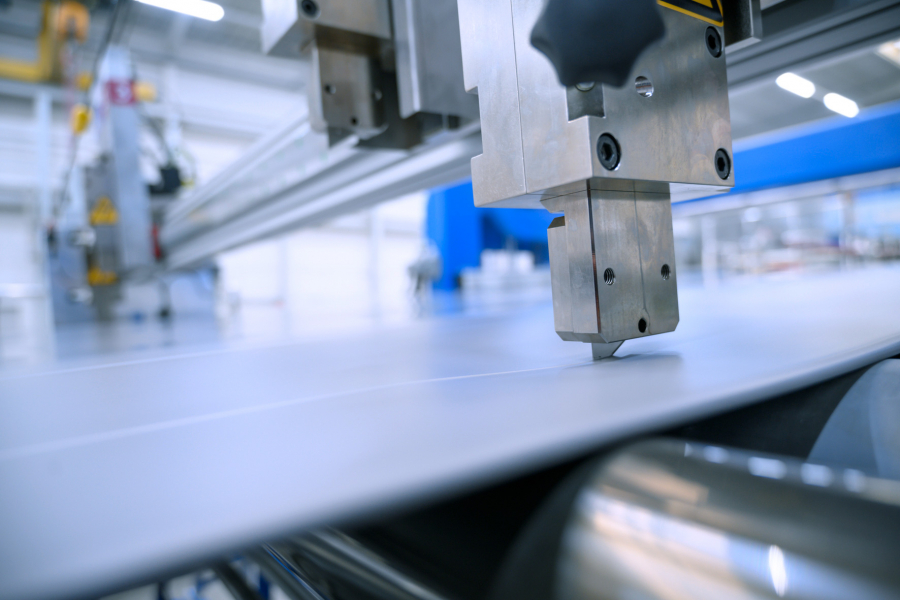

| Sheet thickness | 1 - 20 mm |

| Sheet width | 1000 - 2500 mm |

| Output performance | 500 up to 1500 kg/h |

| Materials | ABS, ASA, PMMA, HIPS, TPU etc. |

| Versions | mono and co-extruded, smooth, embossed, filled, foamed |

Examples of application

Snowmobile

Caravans

Housing for automotive applications

Shower cabine made out of ABS-PMMA sheet

Akustic sheet for automotiv application

Modern shower cabine