BREYER IONPress

Calander technology

Sophisticated production of electrode foils for lithium-ion batteries

The new generation of the BREYER IONPress calender represents a milestone in the improvement of lithium-ion electrode foil production.

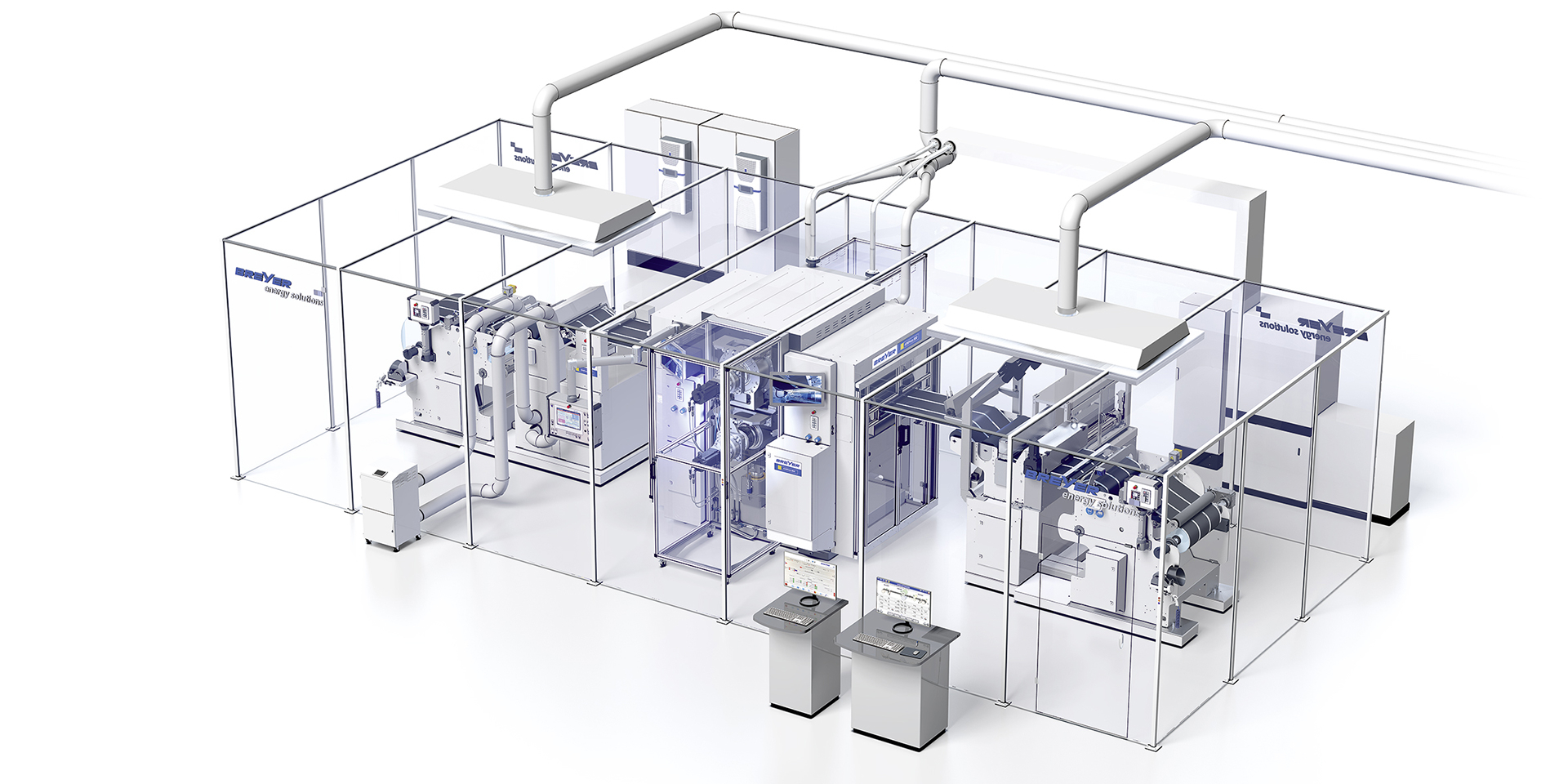

Calander system for lithium-ion electrode production

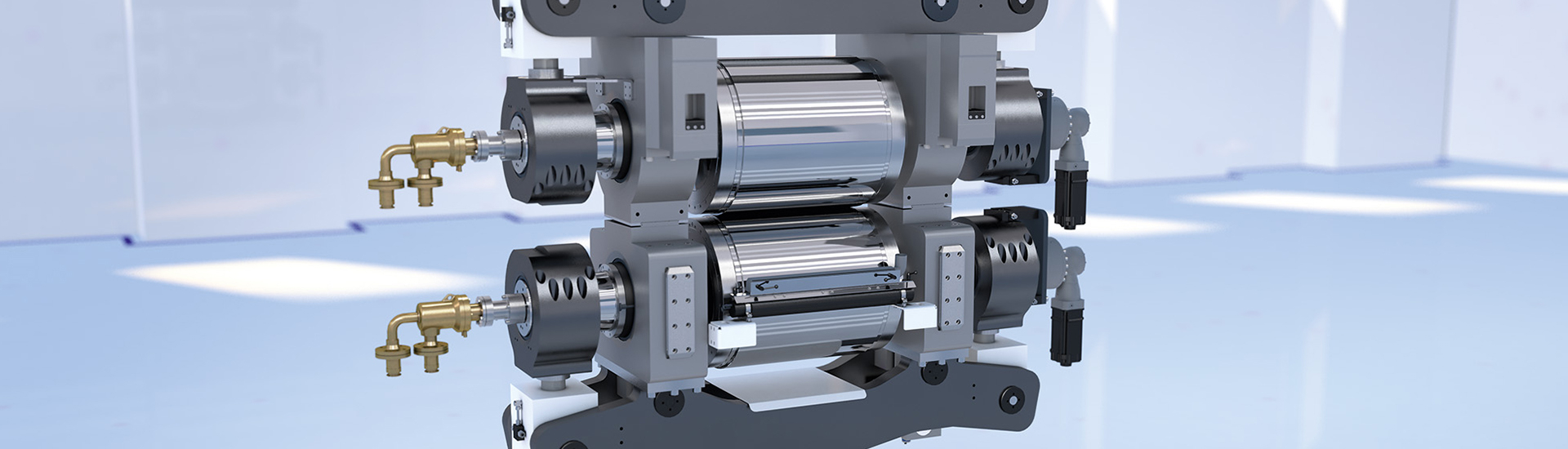

During the calendering process, required properties such as the increase of the power density, optimized electron transport and improved contact between the particles have to be achieved.

BREYER's many years of experience in the field of calender manufacturing made it possible to develop a system that meets the high precision requirements in electrode manufacture. The precise and reliable calender system allows extremely low thickness tolerances.

It is crucial for the operator to be able to set the film thickness reliably, quickly and reproducibly. With the BREYER "fast & easy" gap adjustment technology, adjustment is almost child's play, even in these small dimensions. In connection with the inline thickness measurement, this system allows the construction of an automatic gap control.

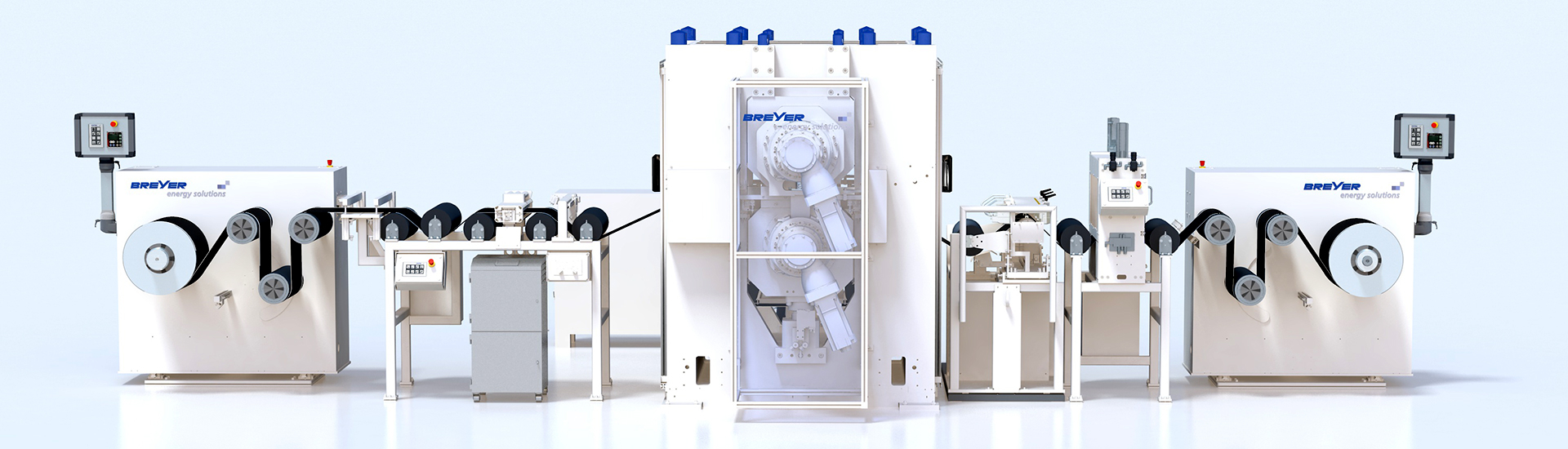

The BREYER technology comprises the calendering of the electrode film in the “roll-to-roll” method. The complete line also includes the unwinding of the coated substrate, the inline thickness measurement, surface cleaning and the winding of the electrode film. Upon request, other system components can be integrated.

The machine is equipped with a color touchscreen and process monitoring system for convenient operation.

ADVANTAGES

- Fast and reproducible thickness adjustment

- Infinitely adjustable line load up to 4000 N/mm

- Direct gap measurement (closed loop)

- High precision compression through servo-hydraulic gap adjustment for distance and force

- Smallest thickness tolerances

- Powerful individual drives

- security system

- Compact design

- Fast Roll exchange (< 3h)

- Counter Bending system (option)

- Convenient user interface, simple operation

SCOPE OF SUPPLY

- Unwinder for manual coil changes up to 50 m/min, with tension control and web edge control.

- Automatic turret winders for highly automated systems up to 100 m/min

- Non-contact web cleaning

- Inspection systems

- Calender IONPress with 600mm or 800mm roll width.

- NEW: Calender IONPress 400 core (laboratory)

- Roller quick exchange system

- Optional counterbending device

- Roller cleaning

- Substrate pre-warming

- Thickness measurement systems

- Track&Trace

- Tension separation via controled haul-off's

- Winder for manual coil change up to 50 m/min, with tension control and web edge control.

- Automatic turret winders for highly automated systems up to 100 m/min

BREYER · Innovations for better Solutions

Contact us and ask about BREYER IONPress.

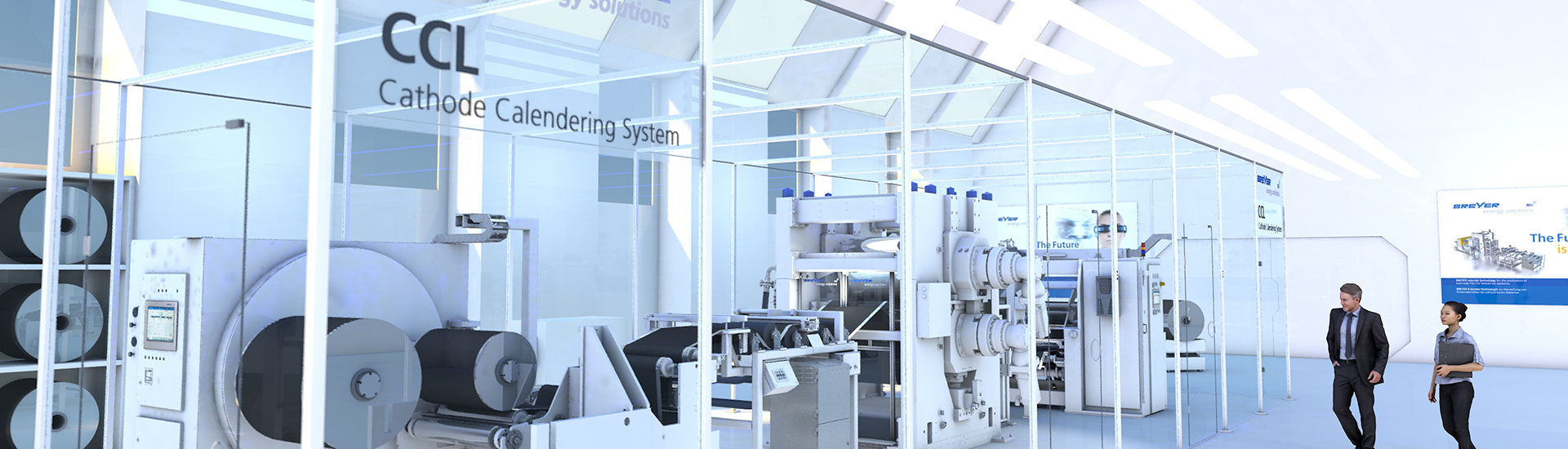

The future has begun - with BREYER energy solutions you will also be at the forefront.

Technical data

| Line speed | 0.5 – 100 m/min |

| Roller temperature control | water / thermal oil |

| Roller widths | 400, 600, 800 mm |

| Roller diameter | up to 800 mm |

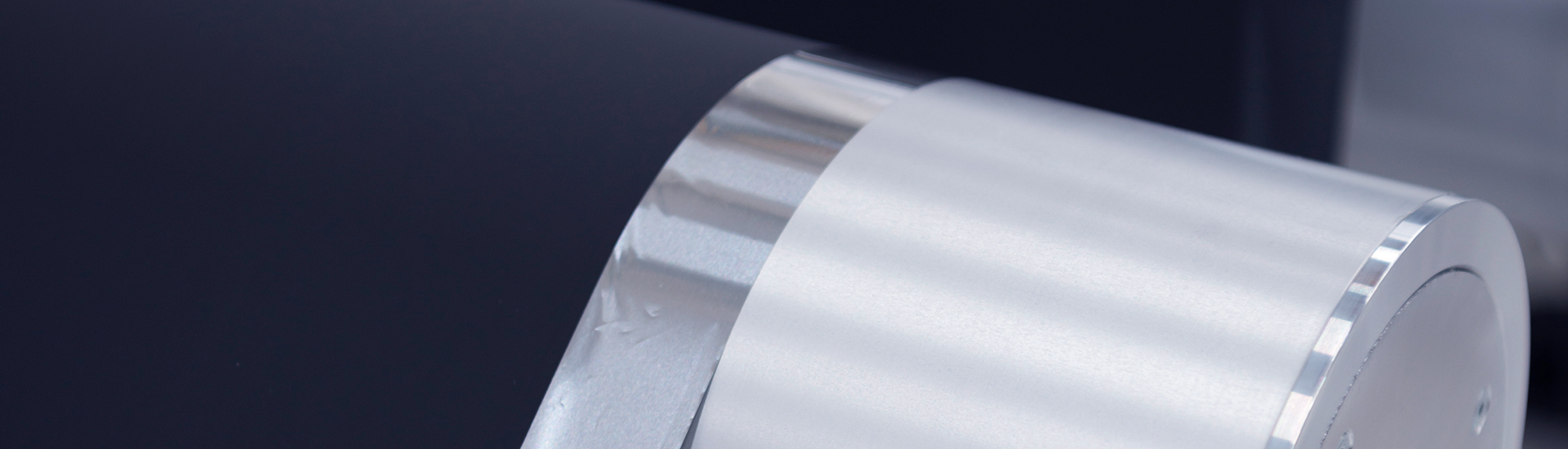

| Roller surface | hard chrome-plated / carbide |

| Roller gap adjustment | servo-hydraulic control |

| Precision | ± 2 µm |

| Line loads | up to 4000 N/mm |

Examples of application

Components

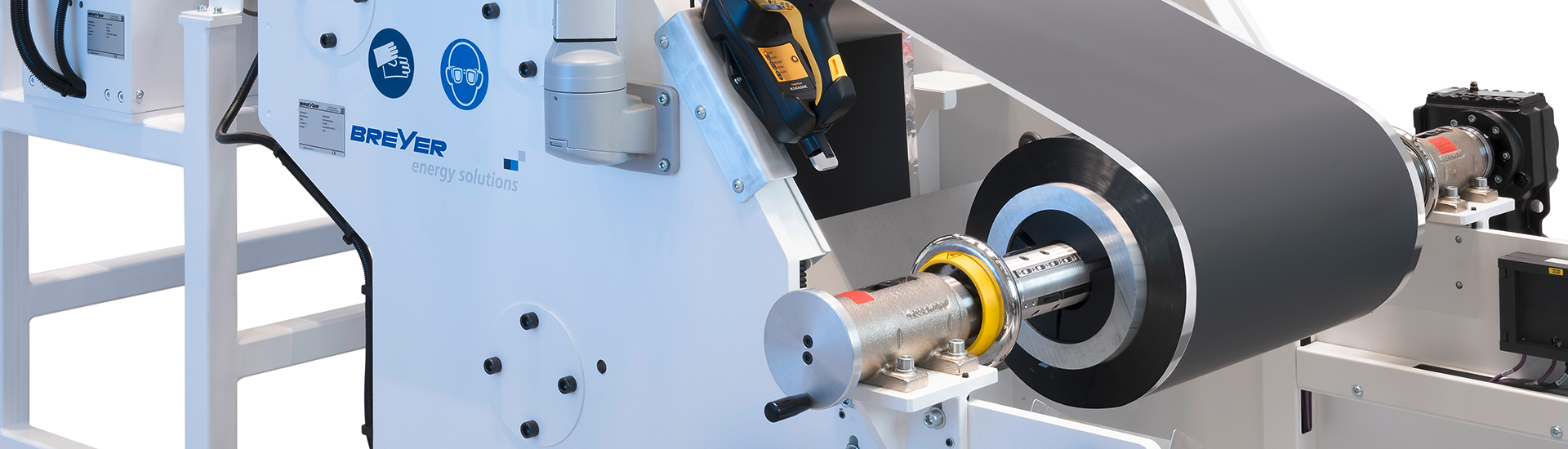

Winding technology

For manual coil change up to 50 m/min or automatic turret winders for speed up to 100 m/min and above.

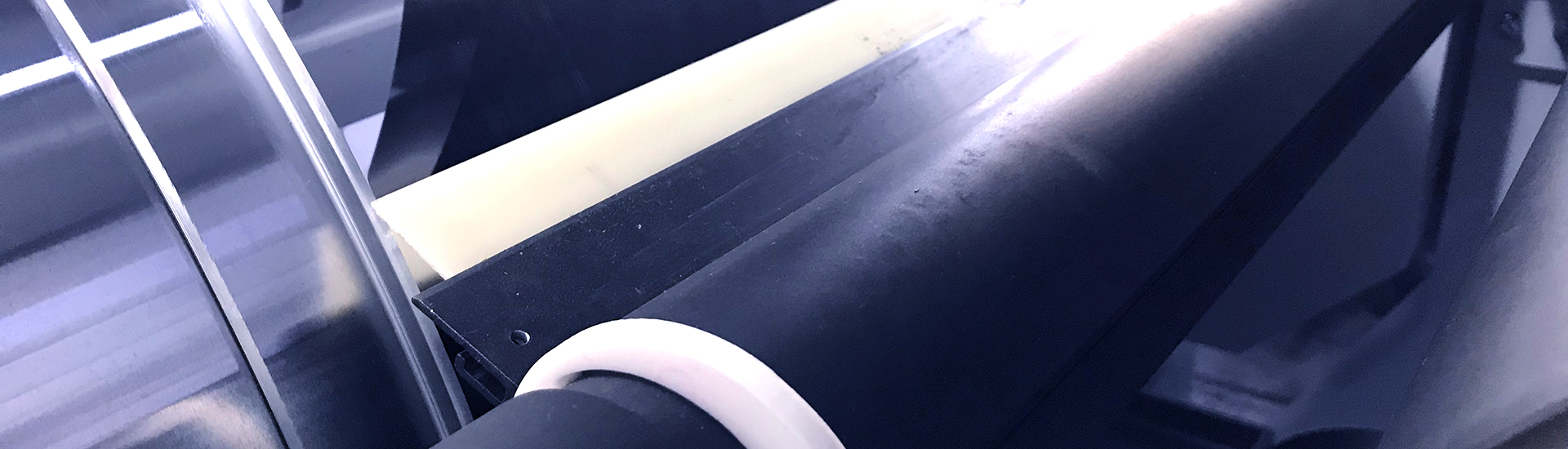

Web cleaning

To clean the surface of the electrode web, it is sucked off at the top and bottom.

Mark detection

To detect marked defects.

Splice detection

Color sensors are installed to detect the splice.

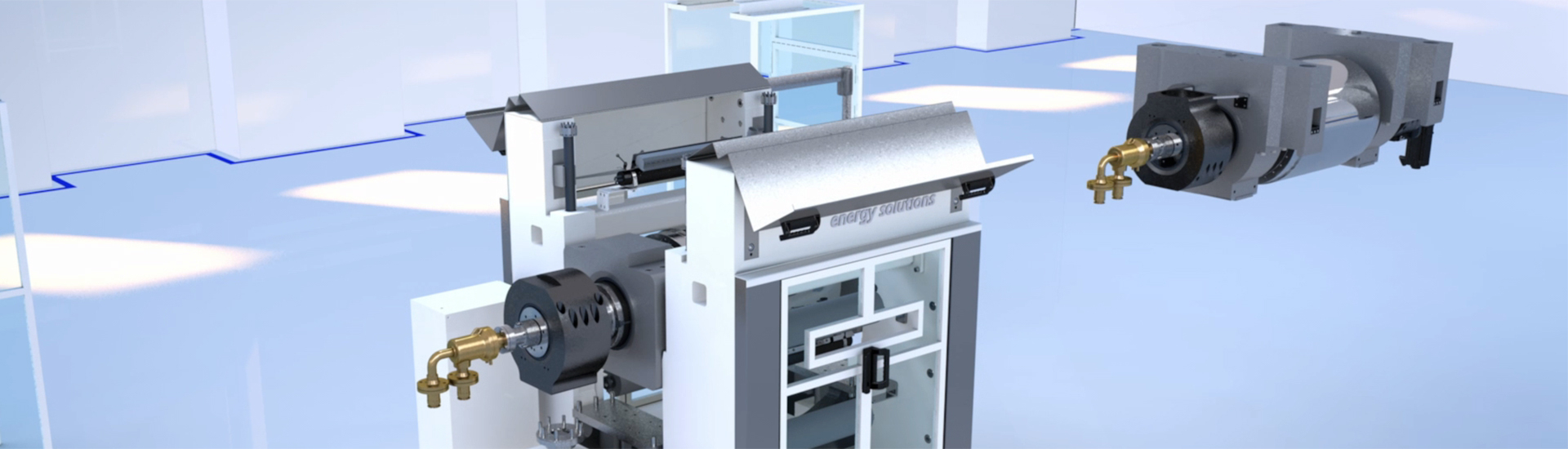

Calender BREYER IONPress

The BREYER calenders of the IONPress series are extremely stable and have a high-precision, fast and reproducible gap setting.

Roll technology

Breyer has many years of know-how in the manufacturing of calender rolls.

Gap adjustment

The patented gap adjustment on the BREYER calender enables a gap and force mode of operation.

Fast roll change

Quick-change roll equipment for changing rolls quickly in record time.

Counter-bending device

To compensate the roll deflection at high nip forces.

Web guidance

Precise film guidance is necessary in order to be able to wind up the calendered film without creases.

Thickness measurement

Recording the calendered electrode thickness.

Roll cleaning

A switchable scraper system is used for the permanent cleaning of particles.

Web guidance

The web guide is divided into different tension areas for an individual setting of the tension forces.

Mass production

Automated calender operation is required for the production of large quantities.