Gap adjustment

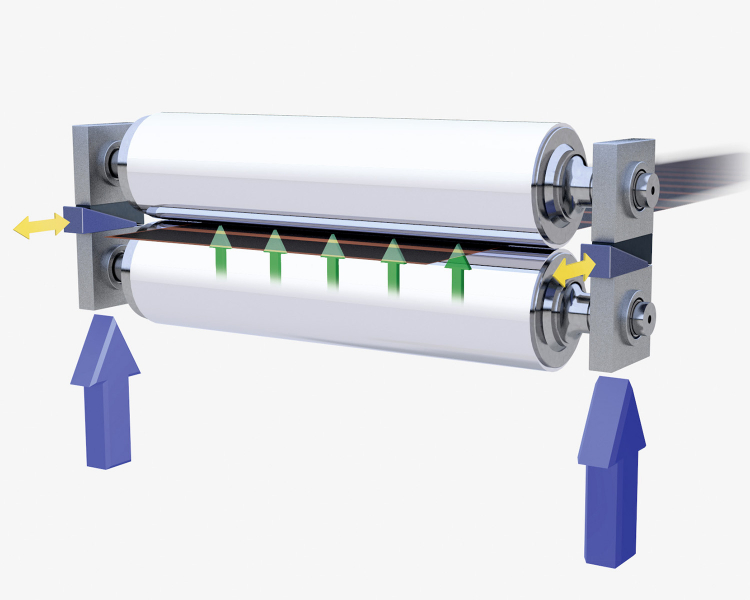

The patented gap adjustment on the BREYER calender enables a gap and force mode of operation.

You can switch between the two modes on the fly. This can be set precisely by measuring the actual value of the gap. The line forces that can be achieved are up to 3800 N/mm. Electrodes with continuous or intermittent coating can be processed.

Power-saving pressing

Thanks to the special non-stop roll positioning system, the hydraulic pressing force is transferred to the substrate surface with almost no loss. This allows you to work with the lowest possible pressing force, which minimizes the distortion of the electrode track.

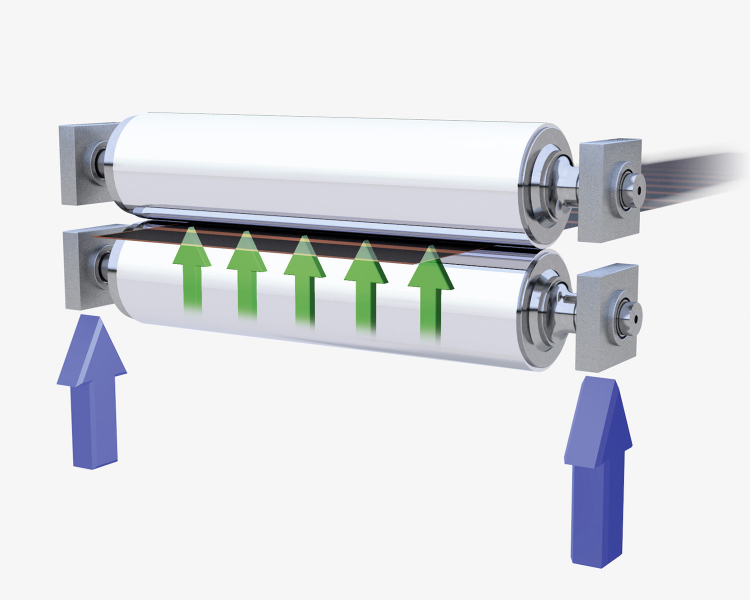

Direct flow of power – the advantageous BREYER principle.

With the BREYER calender technology, the power flow runs directly via the roll onto the coating. The force and the product thickness can be set in a defined manner.

For comparison – the only indirect power flow in conventional calenders. In conventional calenders with mechanical adjustment systems between the rolls, part of the force is diverted via the adjustment system and therefore does not reach the product surface. Higher line forces are necessary. Bearing and machine are more heavily loaded. Adjusting the product thickness is usually difficult.

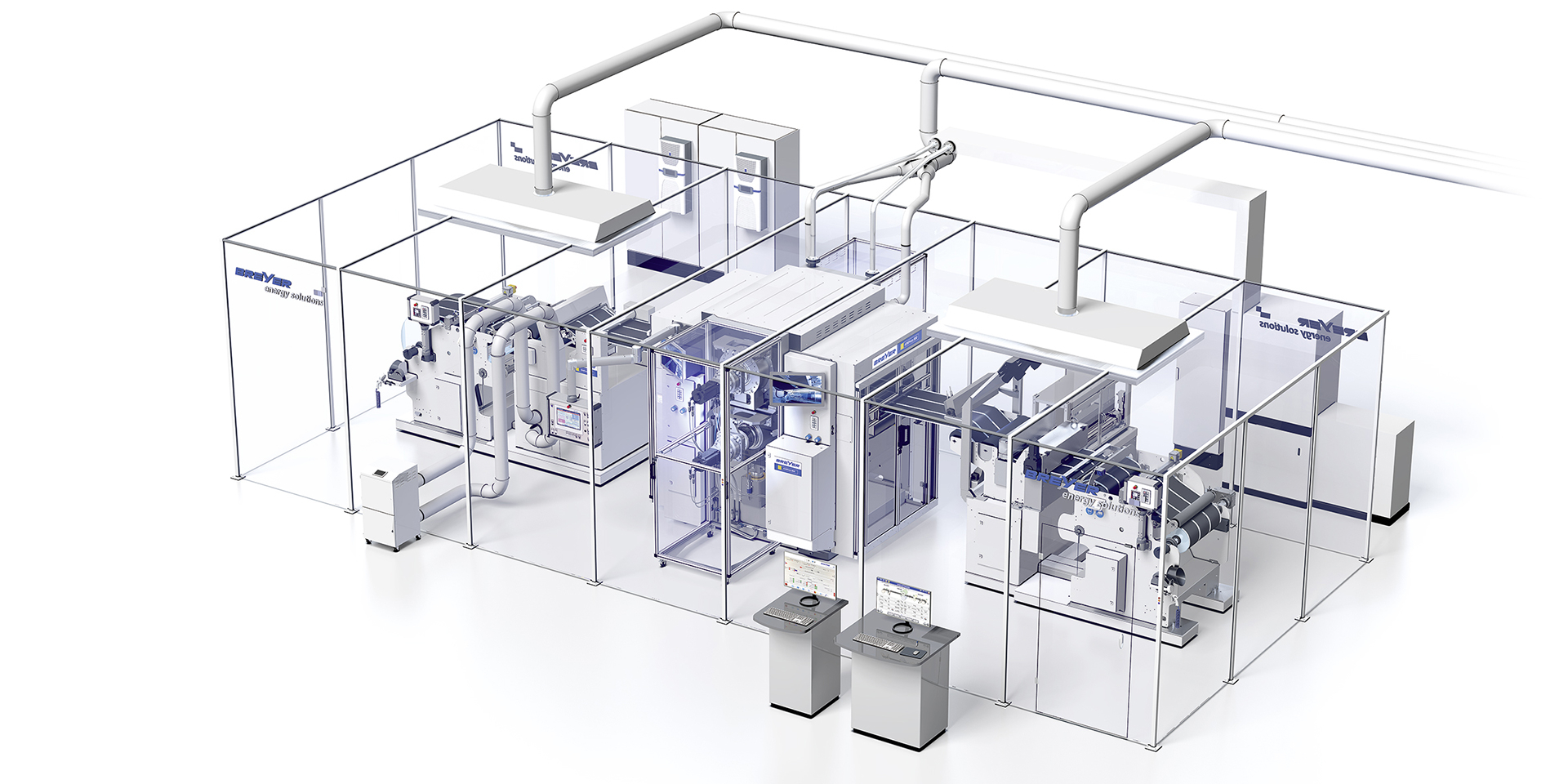

BREYER IONPress

Calander technology

The new generation of the BREYER IONPress calender represents a milestone in the improvement of lithium-ion electrode foil production.