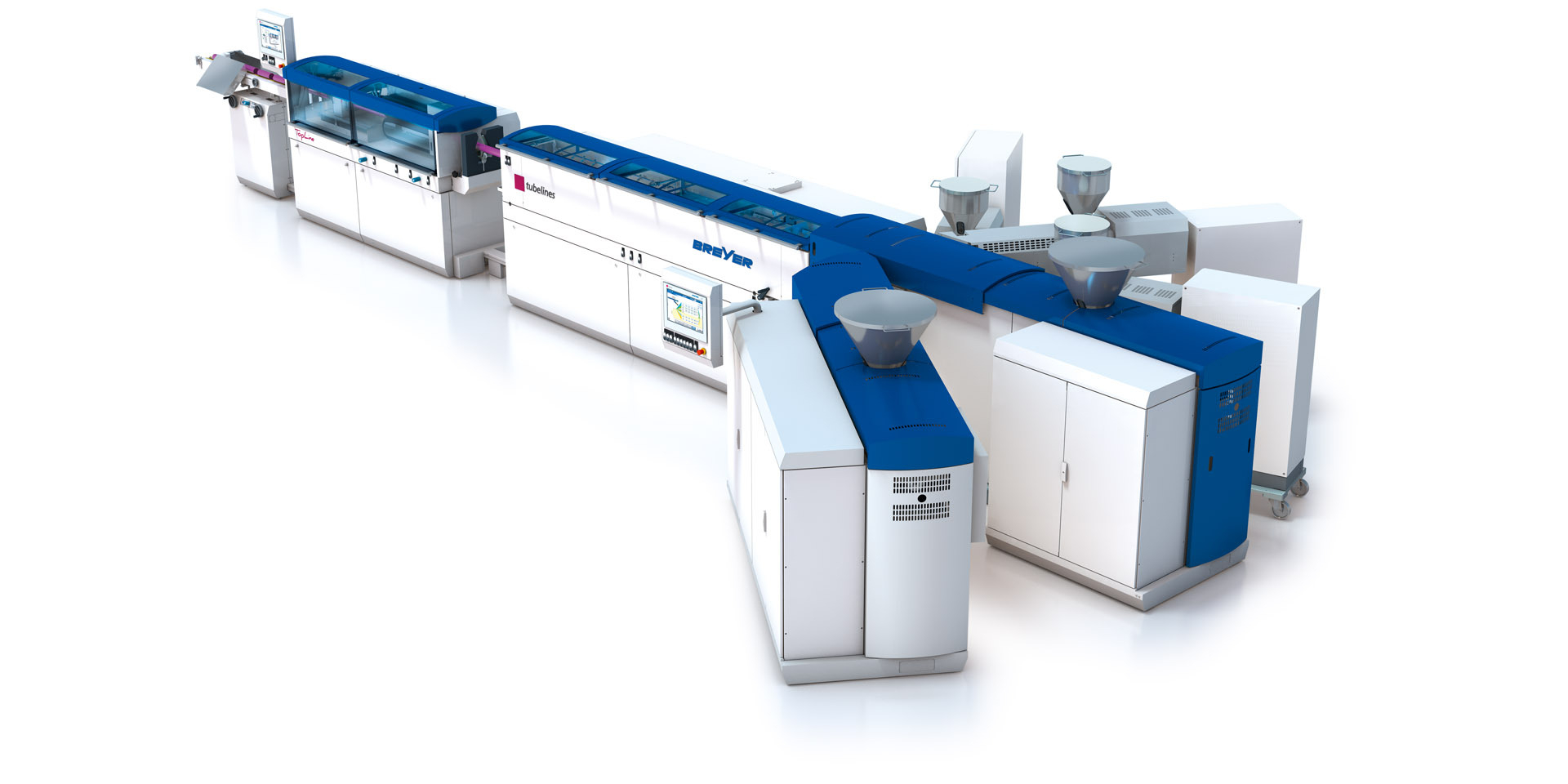

BREYER TopLine

Extrusionsanlage zur Herstellung von Tubenschläuchen

Hochleistungs-Tubenschlauchextrusion –

Tubenschläuche nachhaltig, flexibel und mit hoher Leistung produzieren.

Schnelligkeit und Qualität stehen heute in vielen Fertigungsprozessen an erster Stelle. Gut, wenn man dann auf eine Technik zurückgreifen kann, die selbst bei hohen Geschwindigkeiten konstant gute Qualität liefert.

Denn hier entscheiden oft perfektes Aussehen und Haptik über Erfolg oder Misserfolg eines Produktes.

Neues Maschinendesign

Neues, ästhetisches Maschinendesign welches zum Anspruch der Tube passt.

Intelligentes Energiemanagement

- für bis zu 20% geringere Energiekosten

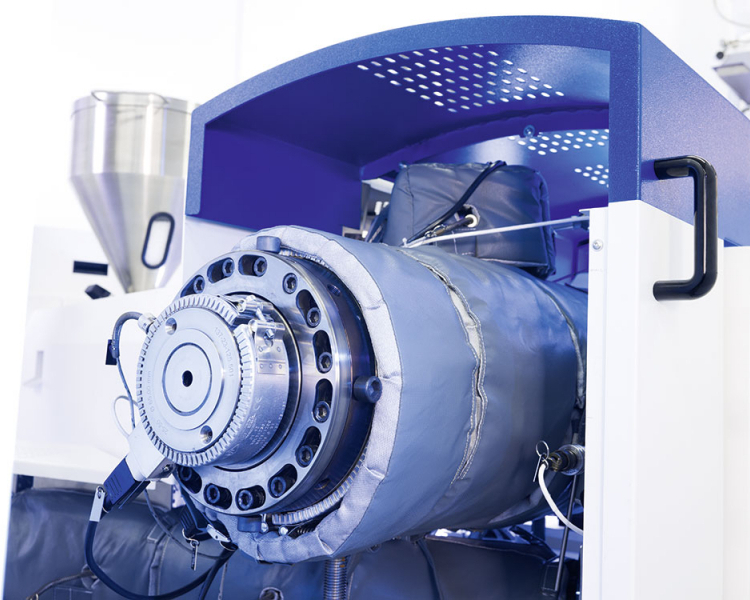

- Getriebelose Direktantriebe / wassergekühlte Torque-Antriebe

- Kühlgebläse mit Klappensteuerung

- Wärmeisolation für Zylinder und Rohrkopf

- Anfahrfunktion und Stand-by-Funktion

- Peak reduction

Der intelligente Weg, um Energie und Kosten zu sparen finden Sie hier...

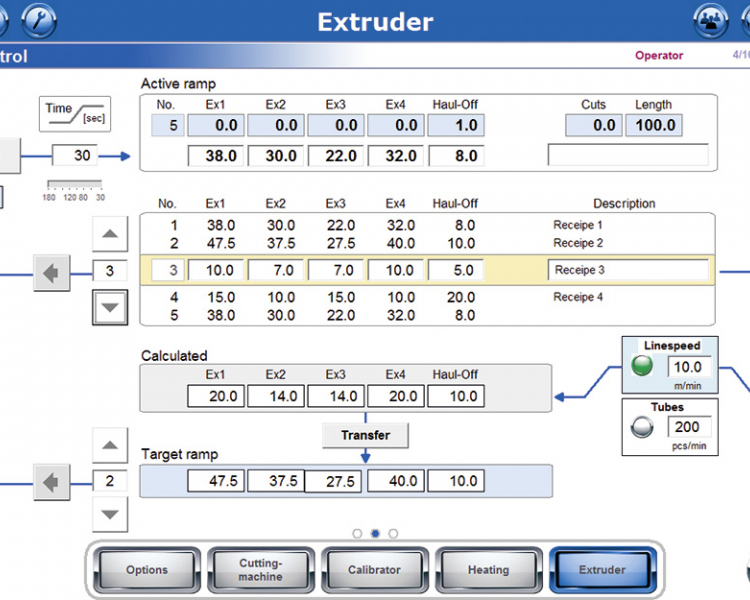

Prozessdaten Überwachung

Aufzeichnung und Steuerung der eingestellten Parameter und Produktionsdaten, Rezeptverwaltung und hohe Wiederholgenauigkeit der Produktionseinstellungen bzw. der Produktqualität.

Neues Bedienterminal

- Verständliche und benutzerfreundliche Software aufgebaut in verschiedenen Stufen

- Verschiedene Ausbaustufen

- Rezeptverwaltung

- Qualitätsmanagement

- Service Seiten · Ferndiagnose

Vorteile

- Funktionelles Anlagendesign

- Kosten- und energiesparende sowie geräuscharme Modulbauweise

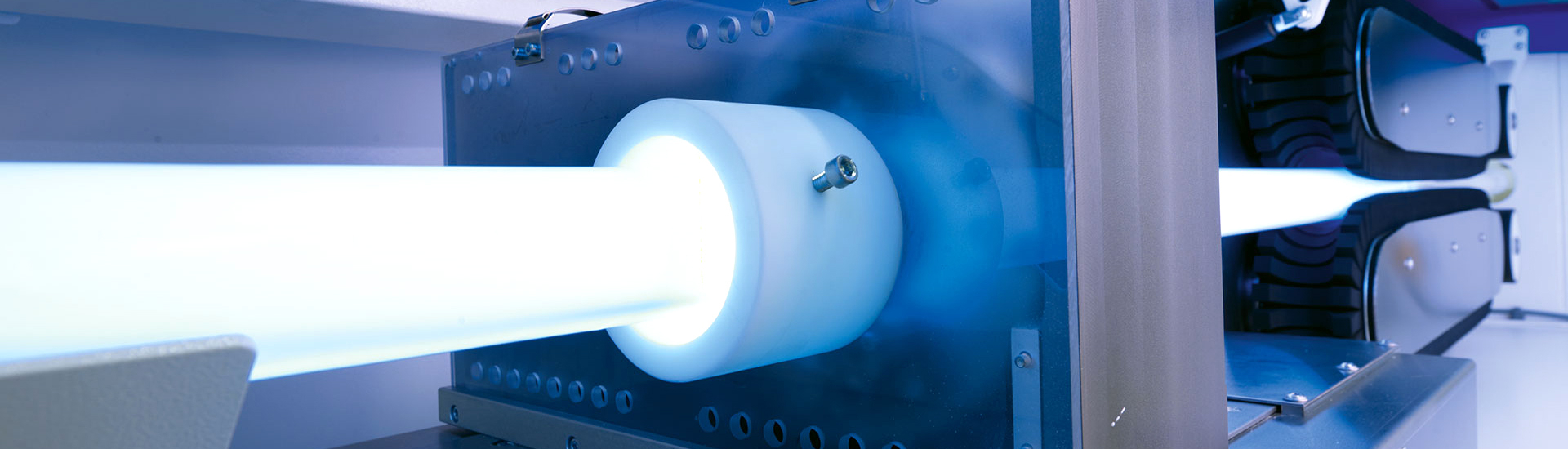

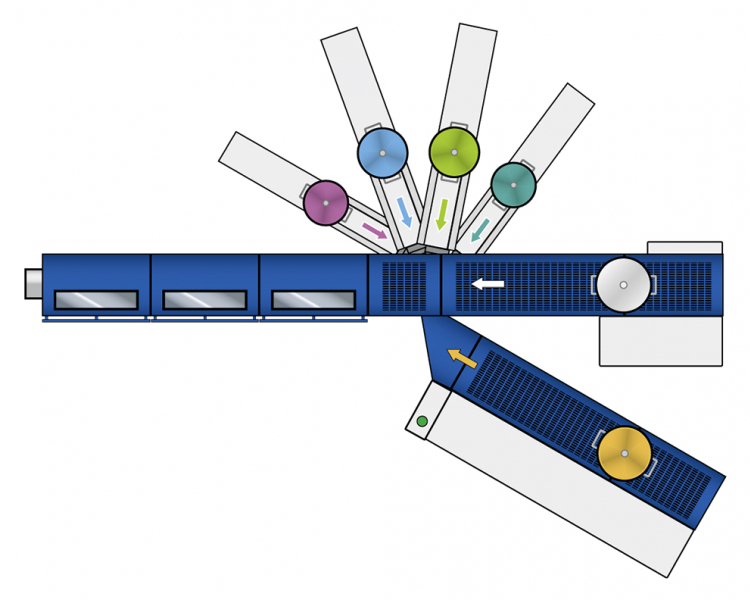

- Unterschiedliche Anlagenkonfigurationen für mono- und coextrudierte Tuben

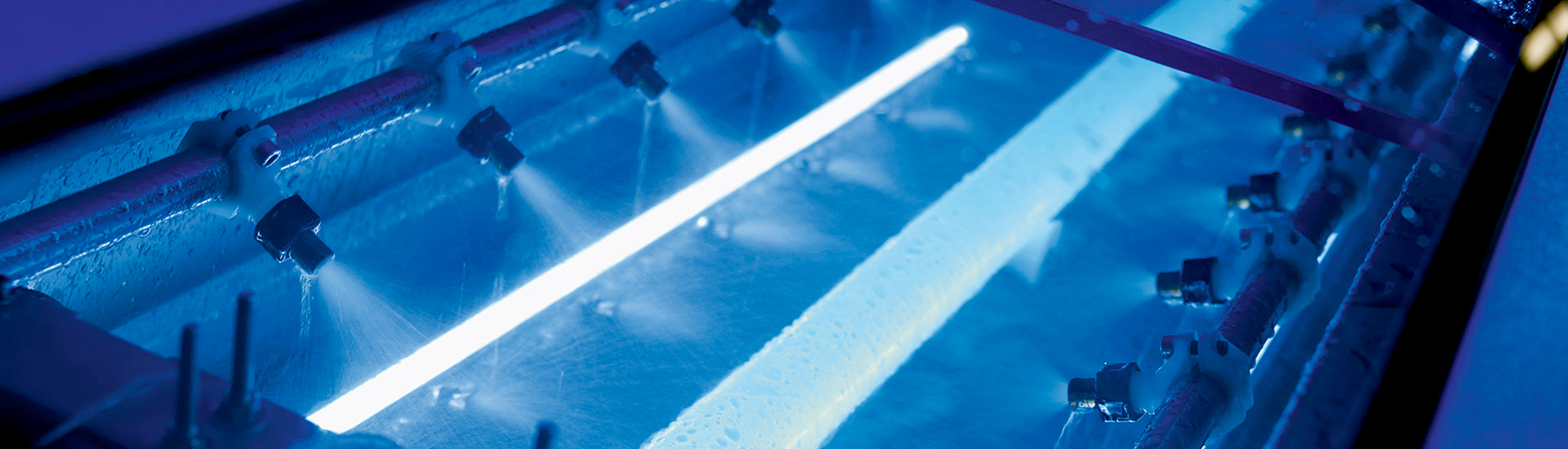

- Hohe Leistung für bis zu 45 m/min Anlagengeschwindigkeit.

- Moderne Antriebstechnologie

- Benutzerfreundliches und modernes Bedienterminal

- Verbesserte Anordnung der Systemkomponenten – wartungsfreundlich und platzsparend

- Qualitätskontrolle und Prozessüberwachung zur Überwachung der Tubenqualität

- Geräuschreduzierung ca. 11 dB (A)

Technische Daten

| Tuben Durchmesser: | 13 – 60 mm |

| Längen: |

30 – 250 mm |

| Leistung: |

80 – 300 Tuben/min |

| Materialien: |

LDPE, LLDPE, MDPE, HDPE, PP, PCR/PIR/Bio, Mischungen. Sondermaterialien auf Anfrage |

| Ausführungen: | Ein- und mehrschichtig, bis zu 7 Lagen, auch mit Fenster |

Anwendungsbereiche

Tuben für Körperpflegeprodukte

Technische Anwendungen von Tuben

Zahnpflegeprodukte in Tuben

7-Schicht-Extrusion