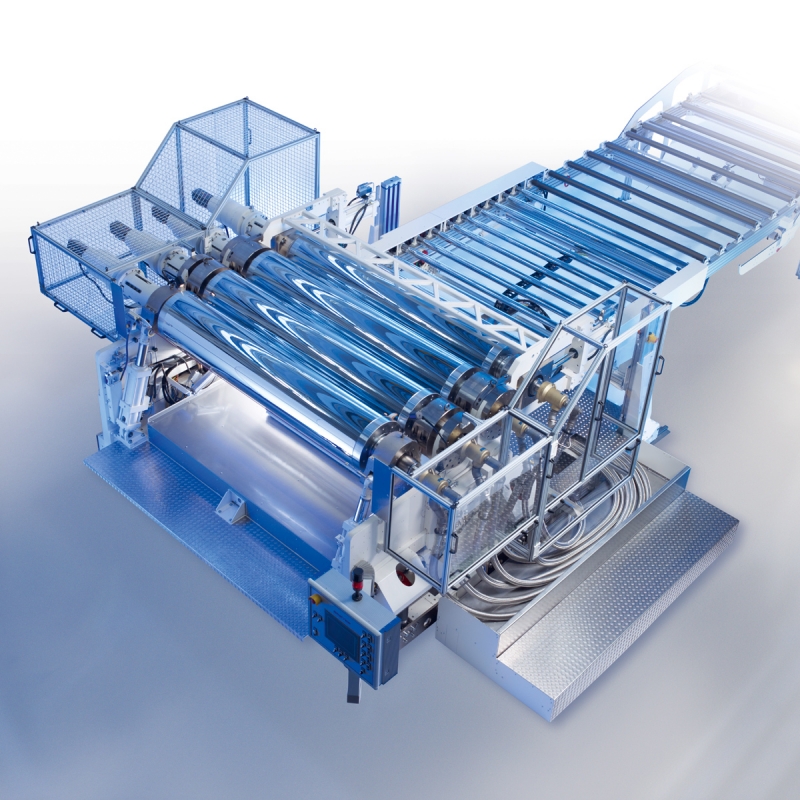

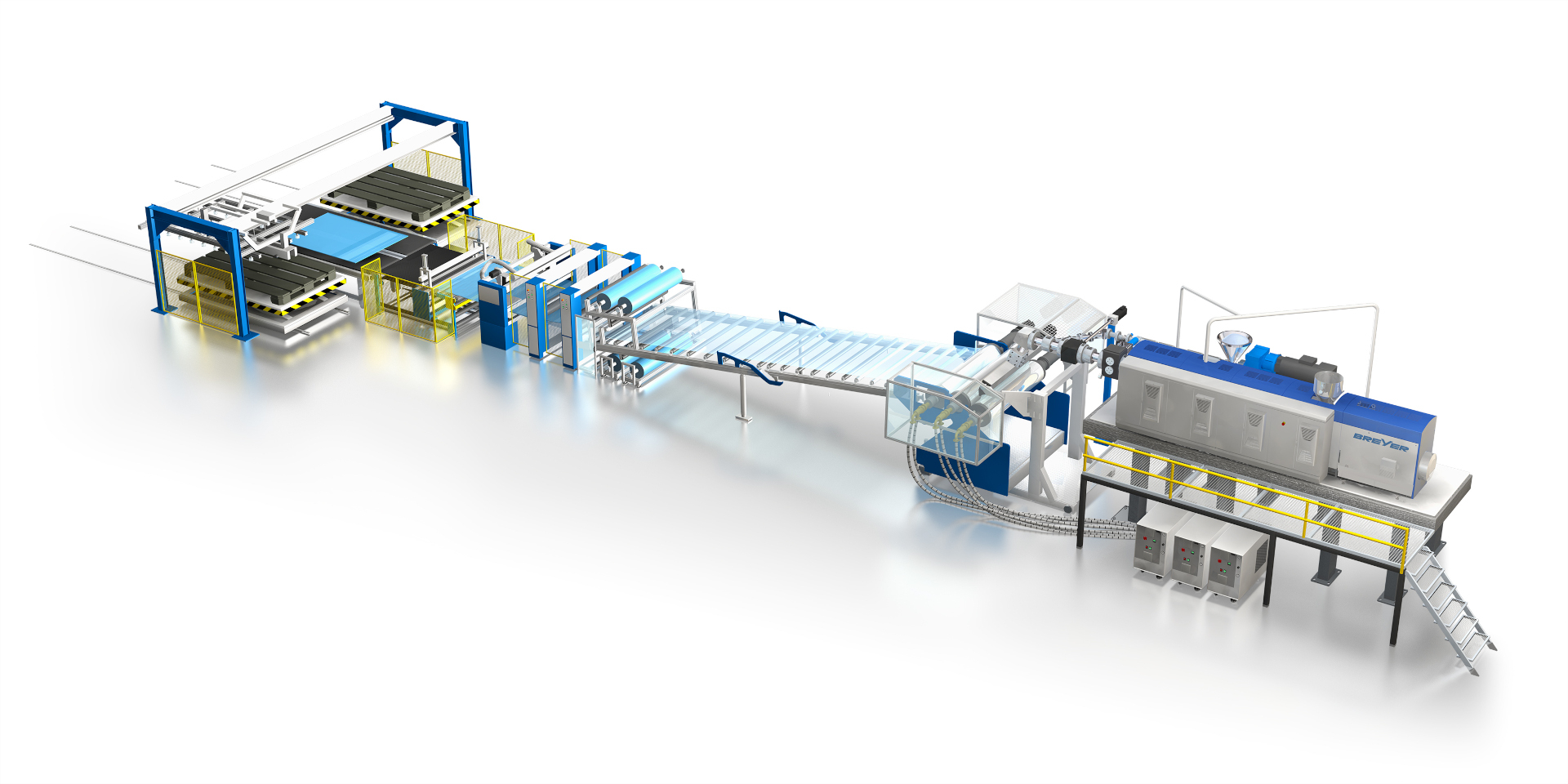

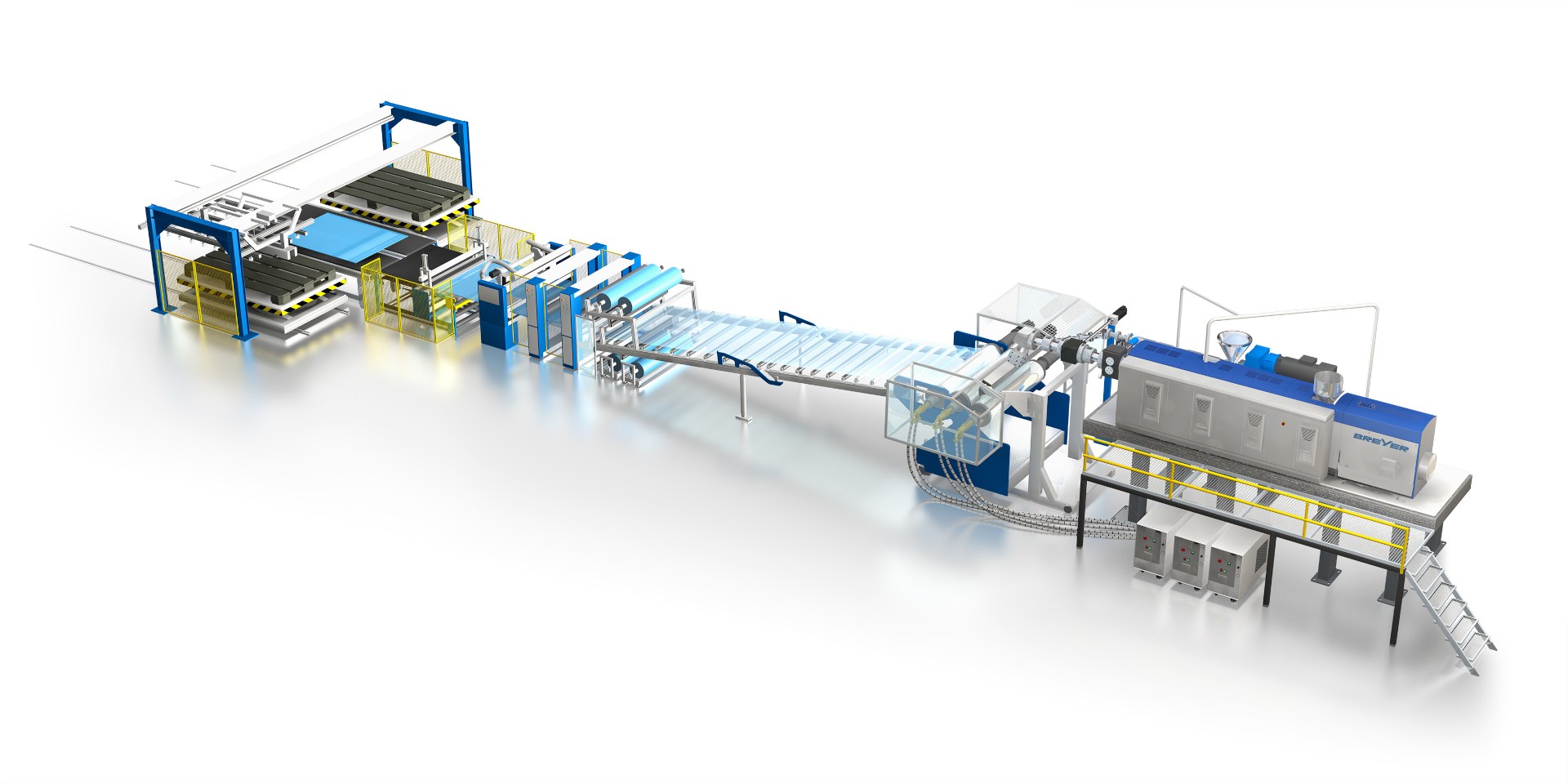

Calender for sheet production

BREYER Calender - the quality hub of your extrusion line

A BREYER calender system not only convinces with its high level of user friendliness but can also be changed from one product to the next at the turn of a hand.

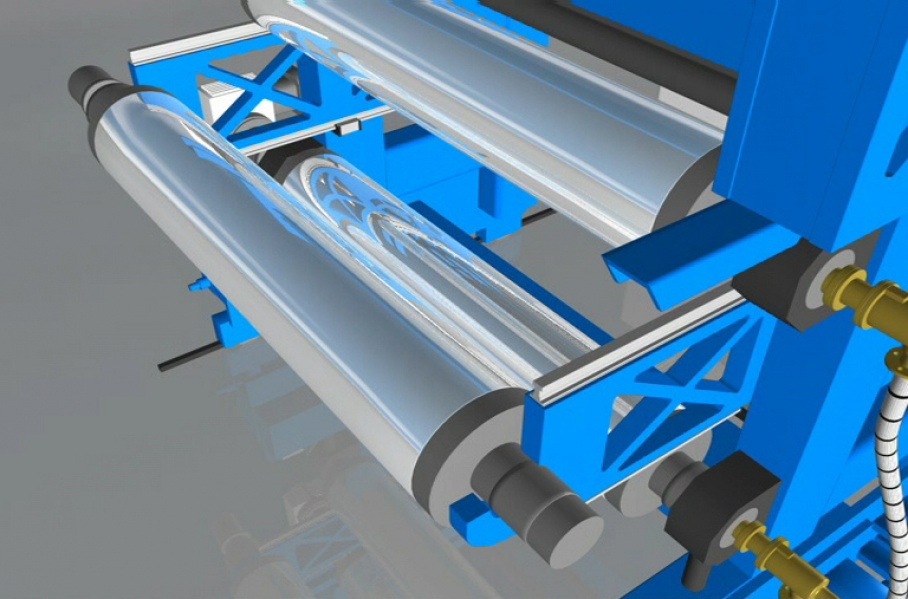

Calender for clear sheet production

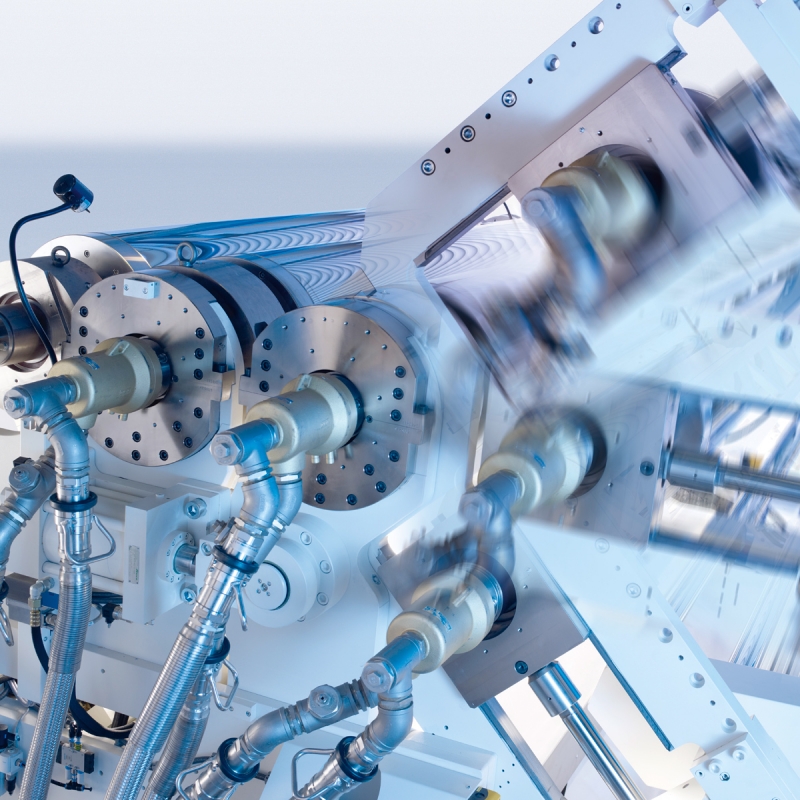

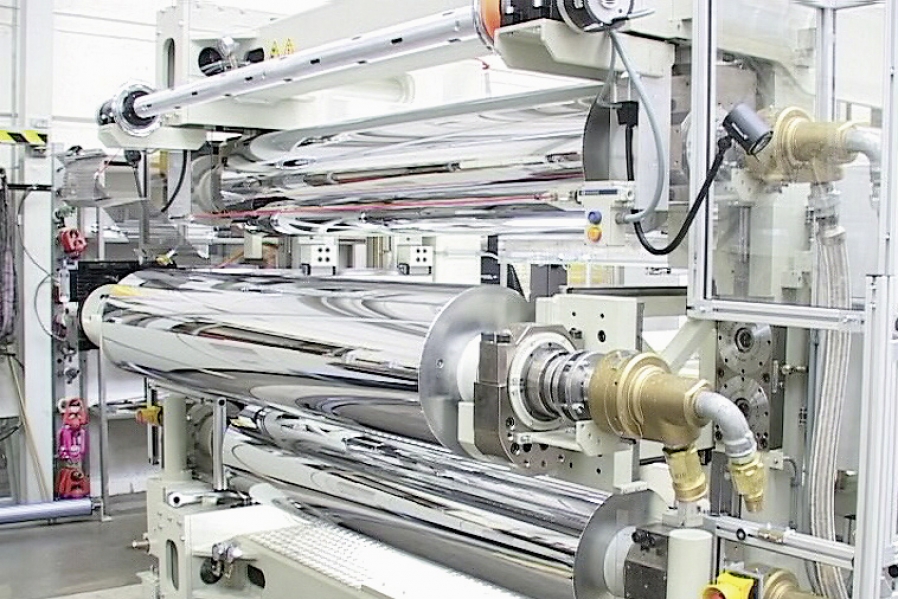

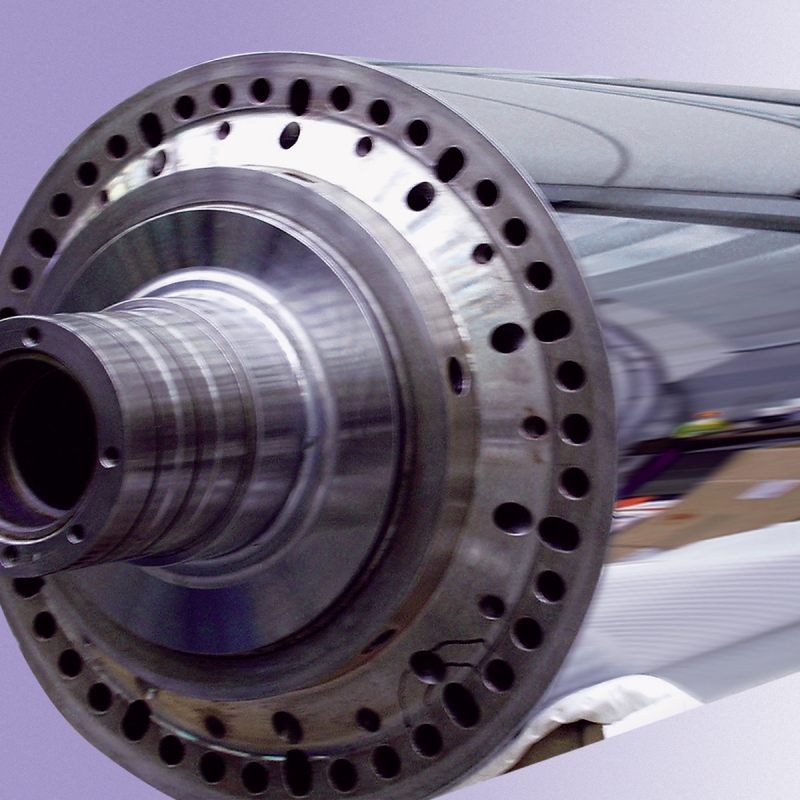

Ultimately, the quality of a clear sheet is defined by the calender. For this reason, we pay particular attention to the chromium plated and high-mirror polished solid calender rolls. These represent the guarantees for producing sheets with perfect surfaces. Thanks to their high precision concentricity and flexural strength, even the thinnest of sheets can be manufactured with extreme accuracy.

The specialists at BREYER came up with an inspired idea to minimize surface defects or cross markings – a drive system based on maintenance-free servomotors and precision gears.

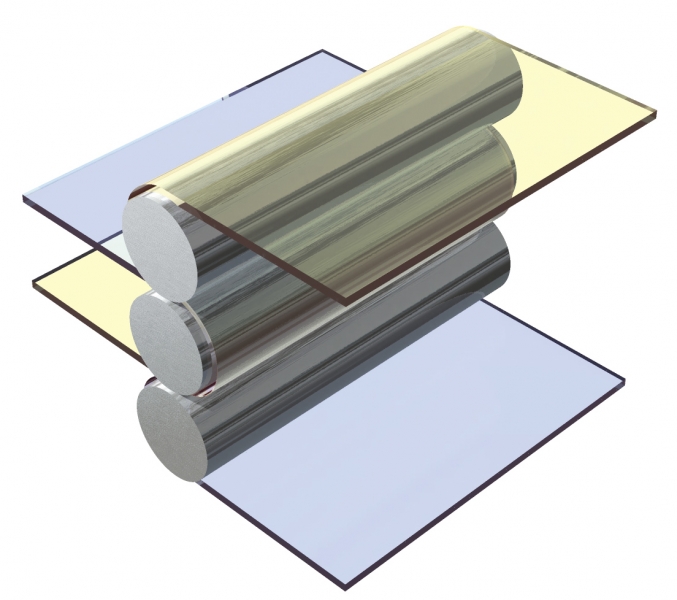

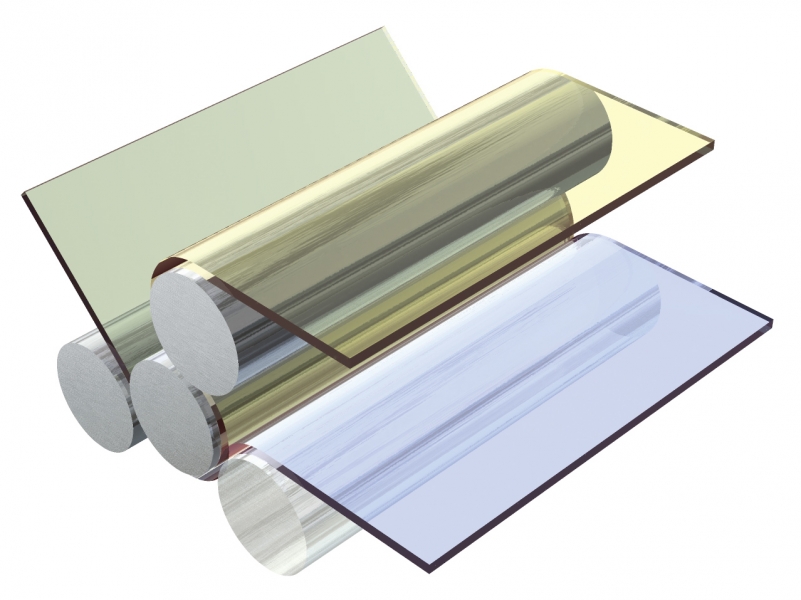

For the manufacturing of clear sheet 3 - and 4 roll calenders are used.

The new 4-roll high performance calender enables the manufacturing of perfect sheet surfaces at high output capacity!

Here, a previously unattainable thickness range between 2 mm and 25 mm is fabricable. The fourth pivoted roll of the horizontally arranged 4-roll calender is the key to success. When the fourth roll is being pivoted downward and the enlacement of the roll is maximised, this results in a high cooling capacity which smoothes the extruded sheet effectively.

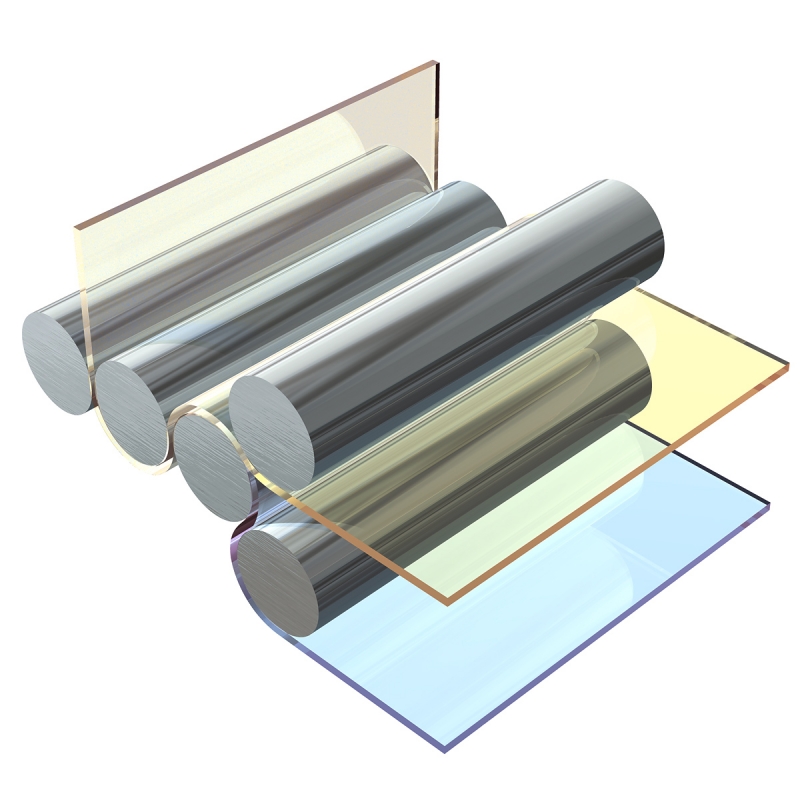

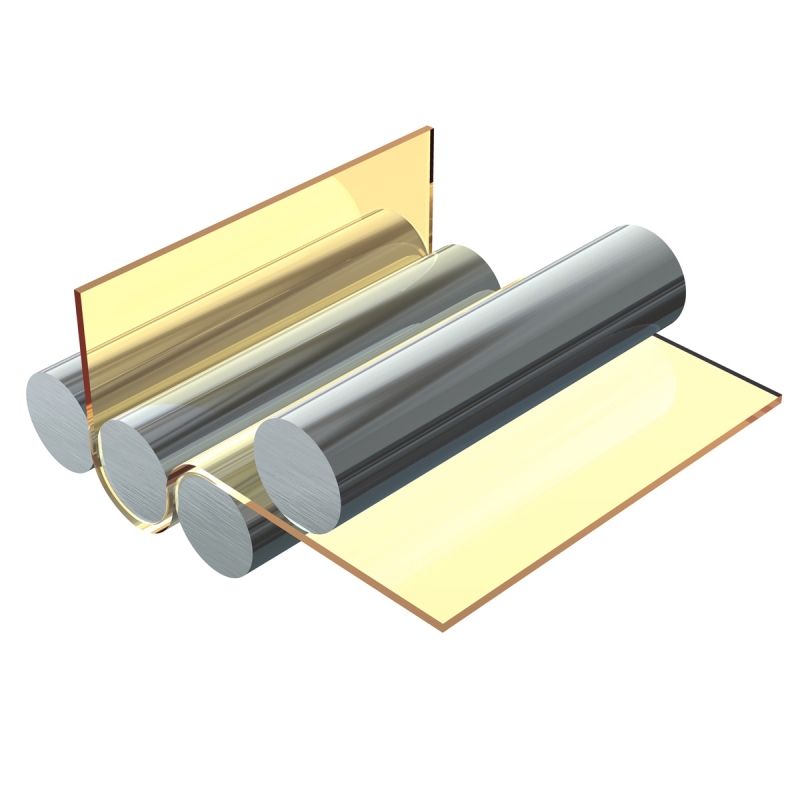

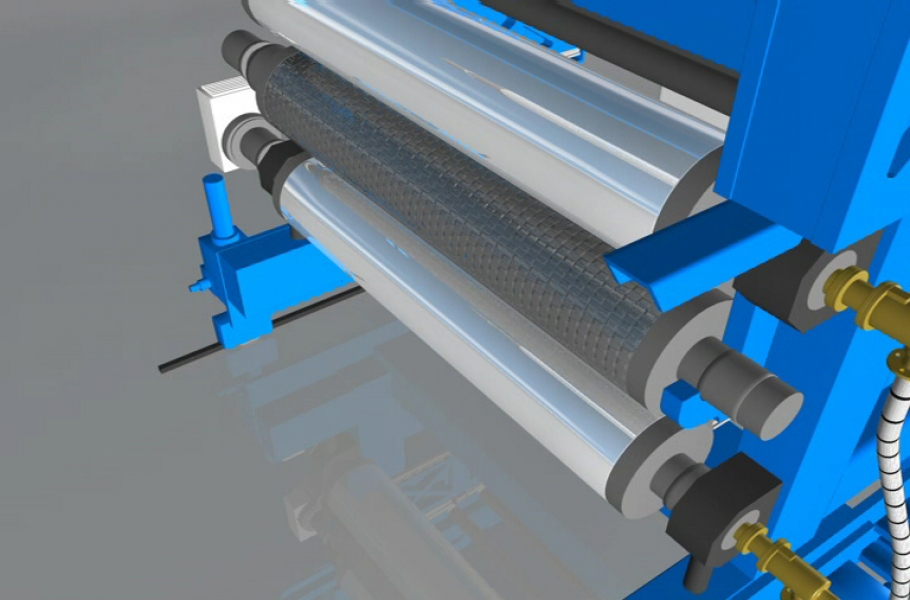

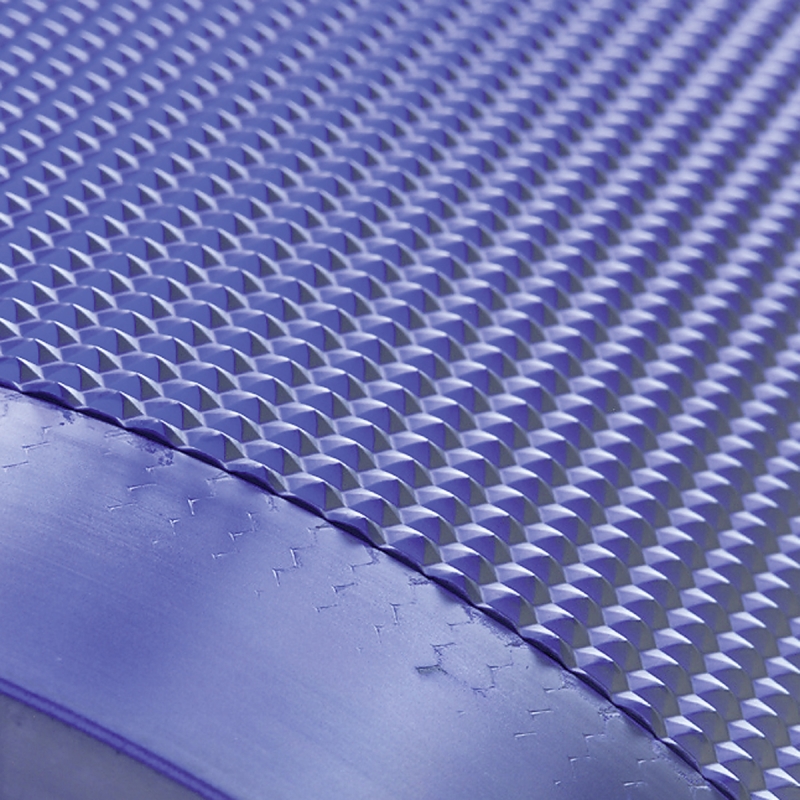

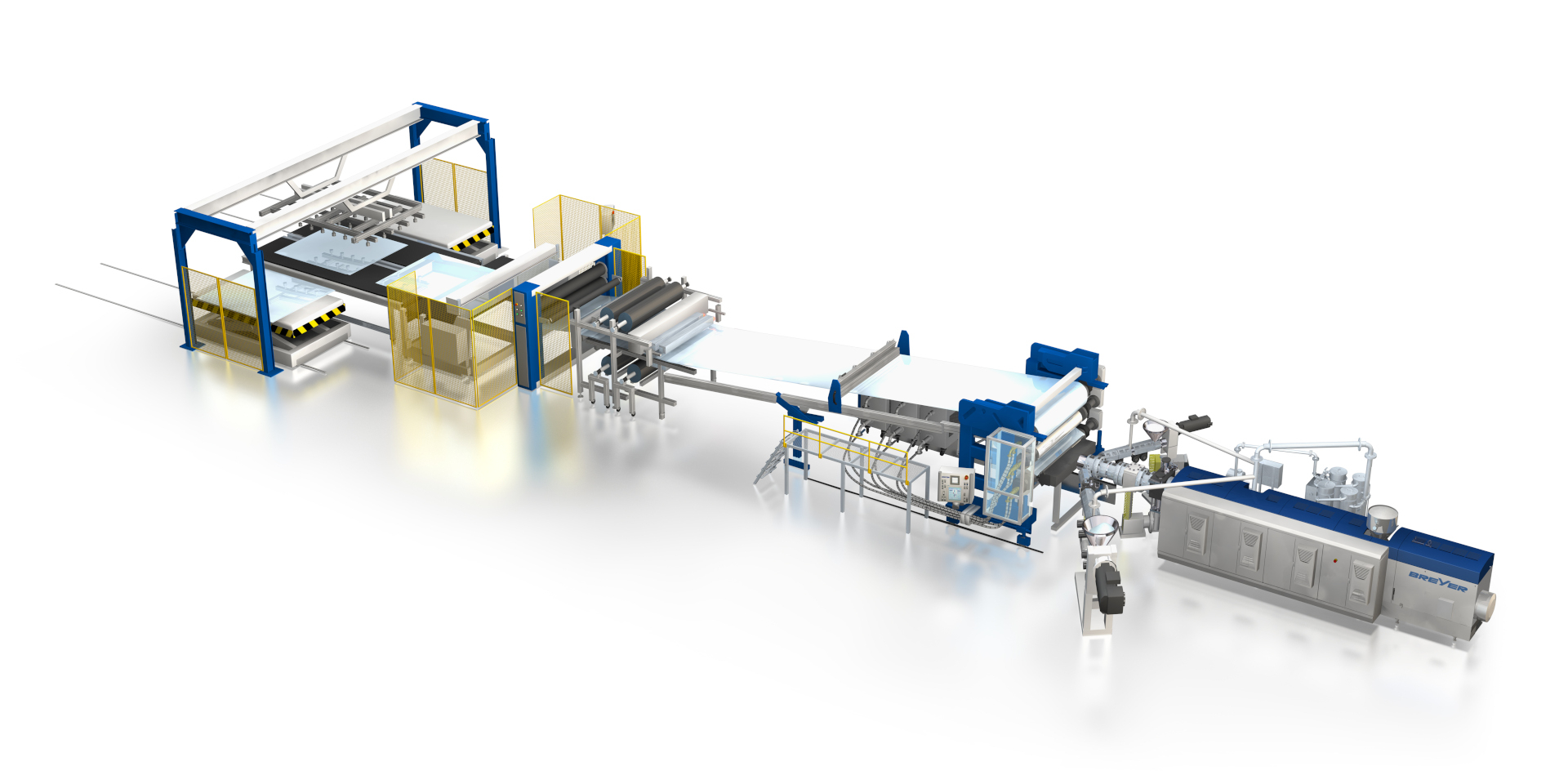

Calender for technical sheet production

The basis of this calender is a vertical roller assembly with a roll diameter of 300-600 mm. This pre-built assembly offers free lateral accessibility and allows viewing into the nip between rolls. Hence, dies with a deckling system can be used without the machine base getting in the way.

Decor foils can easily be run through the roll gap with the aid of a prepared unwinder at the calender. For a quick change of the middle roll it is stored in a drawer that moves out at the push of a button within seconds. It can be replaced with various embossed rolls. This function is literally accommodating because the roll is freely accessible and can be lifted out by a crane.

On the machine's drive and cooling side quick couplers allow a rapid release of the precise connections. The roller is hydraulically locked when retracted and ready for use immediately. With this system the change of rolls is only a matter of minutes and yet another function that adds to the efficiency of the overall system.