Operating for BREYER TopLine tube extrusion line

New generation of Human Machine Interface (HMI) for BREYER Tube Lines

Process Data Recording Monitoring and controlling the adjustment parameters and production data, ideal recipe management and considerably higher repeatability of production data resp. product qualities.

Advantages

- Easy structured user screens

- High definition solution

- Global process value overview

- Role-based user management (Access only to necessary information and data)

- Modular software options

- Structured diagnostic system (Top-Down Analysis for fault indication)

- Browser based trouble shooting

- Individual help pages (based on PDF, AVI, DOC, XLS, …)

- Product oriented recipe management

- Report management

- Midrange trending of important process values

- Remote access (integration into existing customer infrastructure)

- Easy backup and restore mechanism

Comfortable and safe operating via touch screen

Clear structured design - easy to operate

We are user-friendly!

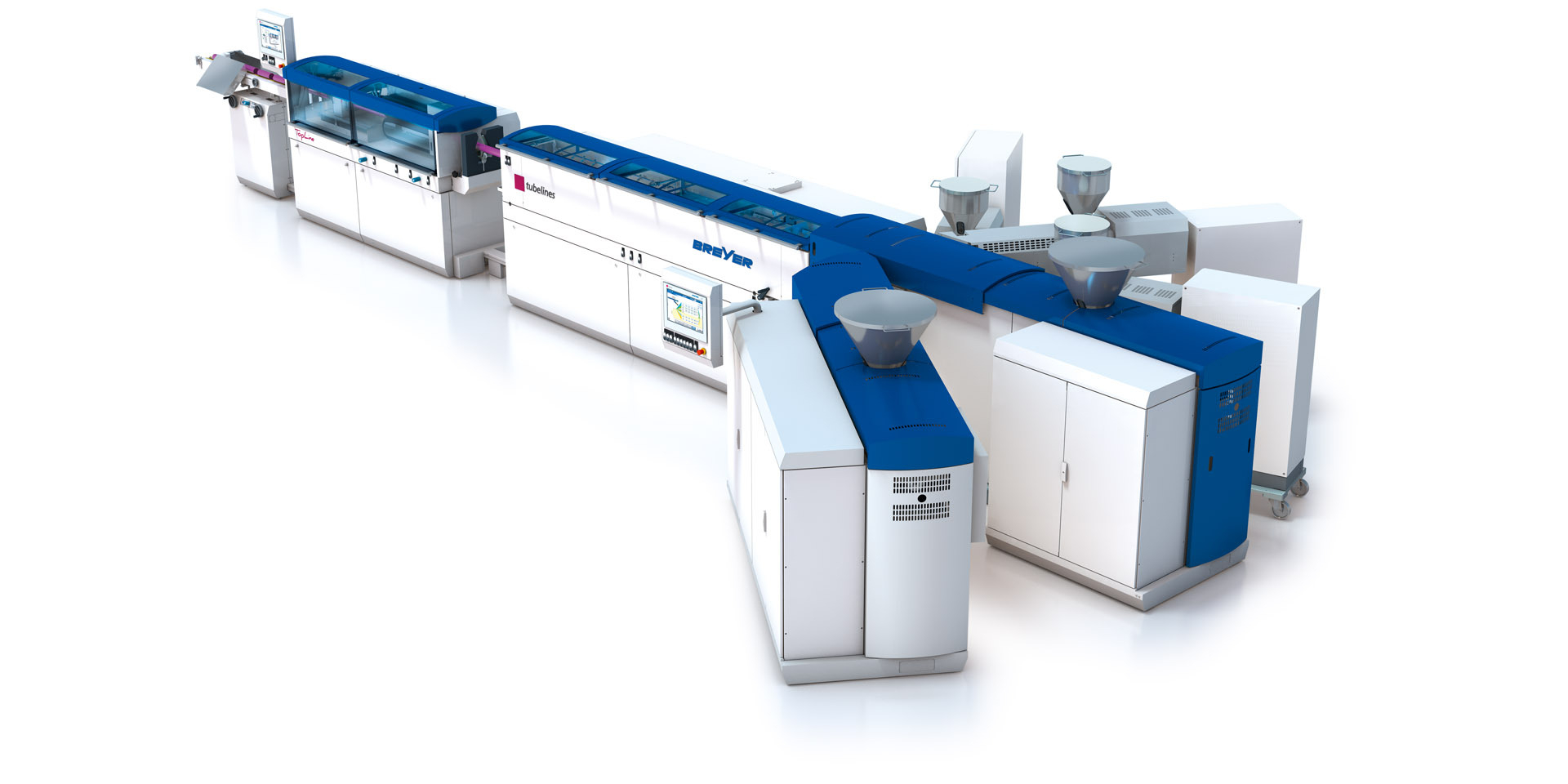

BREYER TopLine

Extrusion line for the production of tube sleeves

Today, speed and quality are top priority in many production processes. It's good if you can refer to a technology that delivers good quality even at high speeds. Clients from the world of cosmetics, which has high standards, know to appreciate this fact.