Komponenten

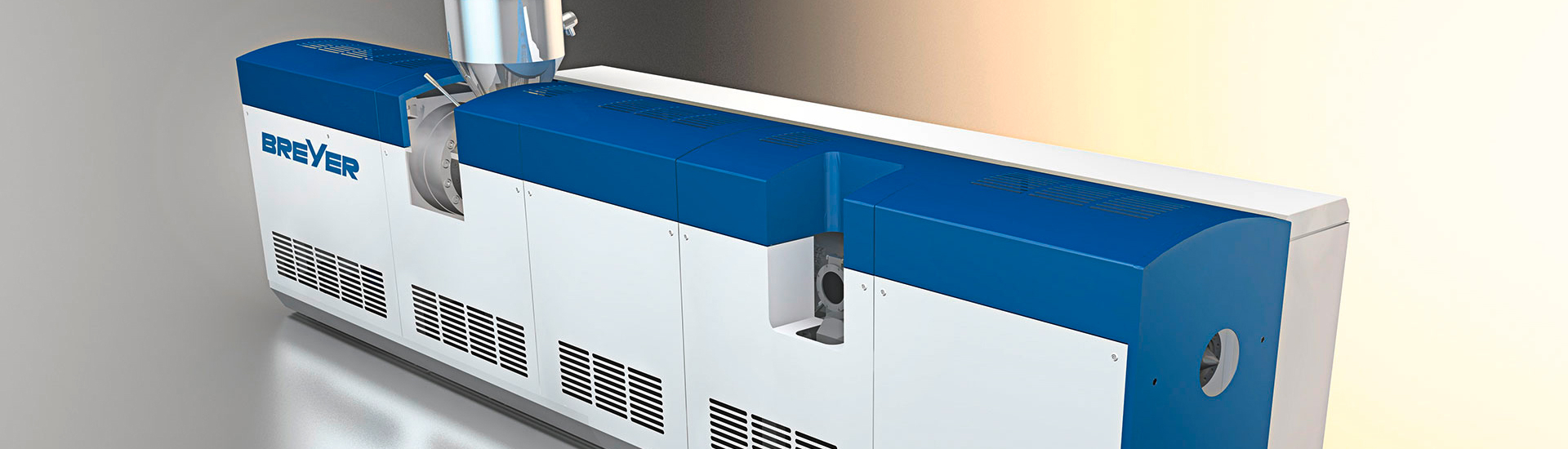

BREYER Extruder

Einer der Kernbausteine einer jeden Extrusionsanlage ist und bleibt der Extruder selbst. Hier setzt BREYER von Anfang an auf Qualität und ausgefeilte Technik.

Einschichtdüse

Das modulare BREYER-Düsenprogramm lässt sich flexibel für eine Vielzahl von Anwendungen kombinieren.

Glättmaschinen für die Plattenherstellung

Eine Glättmaschine von BREYER überzeugt nicht nur durch einen hohen Bedienkomfort, sondern lässt sich auch blitzschnell von einem Produkt auf das nächste umstellen.

Kompakte Temperierlösung

BREYER Temperiergeräte sind kompakte Hochleistungsgeräte für den Einsatz mit Heisswasser bis zu 180°C.

Kaschierung

Um Ihr hochwertiges Folienprodukt zu schützen ist Kaschieren unerlässlich. Dabei wird auf einer oder beiden Seiten der extrudierten Folie eine selbstklebende Schutzfolie aufgebracht.

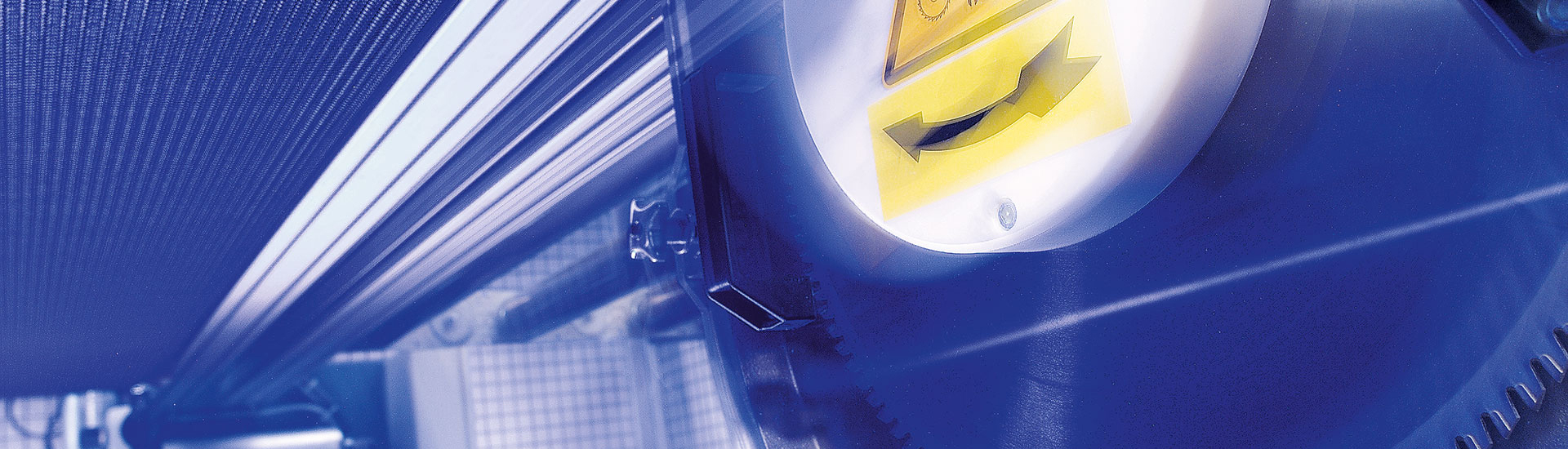

Längstrennsägen

Jede Anlage ist immer nur so gut wie ihre Komponenten. Deshalb kennen wir auch bei den Sägeeinrichtungen keine Kompromisse.

Quertrennsägen

Die lange Lebensdauer, eine vollautomatische Schmierung und der hohe Sicherheitsstandard, wie z.B. Sicherheitseinrichtungen im Einlauf- und Sägeteil, sind wegweisend für diesen Bereich.

Stapelanlagen

Mit einer Stapelanlage entscheidet sich oft die Effizienz einer ganzen Anlage. Denn als Schlusskomponente ist sie verantwortlich für die effiziente Übergabe an die Weiterverarbeitung oder Verpackung.

BREYER Visualisierung

Das BREYER Visualisierungssystem besticht durch seine Einfachheit. Intuitiv wird der Bediener zu den gewünschten Informationen navigiert, und kommt so schnell zum Ziel.