BREYER die and calender roll cleaning

The professional and timely cleaning of the key components of your BREYER extrusion line ensures the high quality and economic efficiency of your production for the future. Therefore BREYER Services offers you cost-efficient and “clean” solutions.

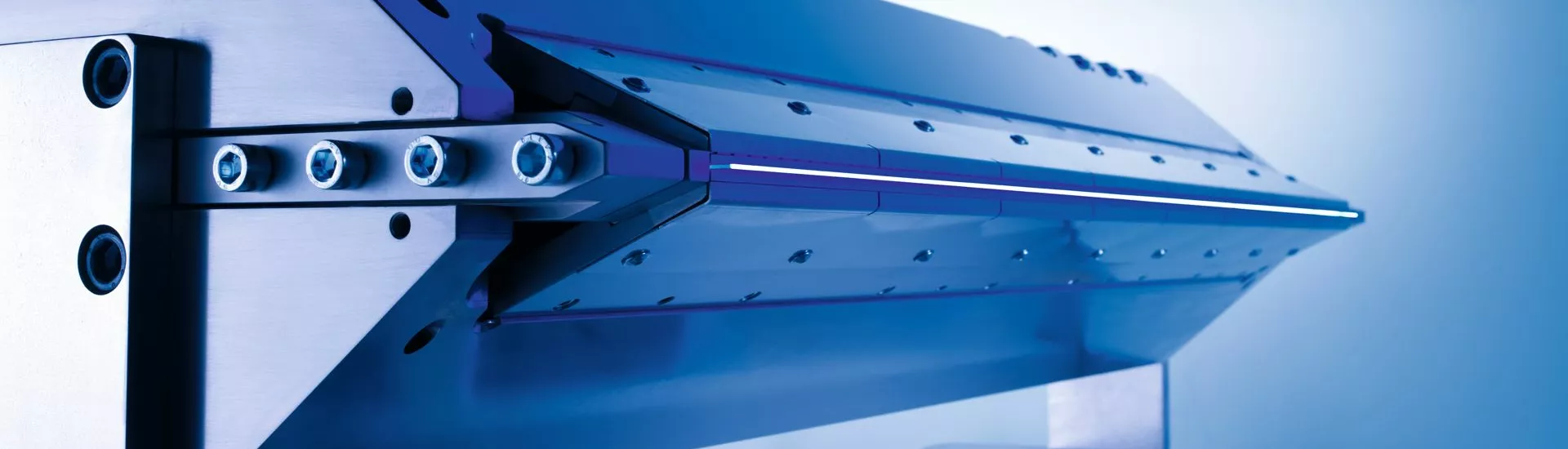

BREYER die cleaning – the key task.

The BREYER film or sheet die is a key element of your extrusion line. In this die your high-quality film or sheet is formed with several very thin layers of plastic and their thicknesses defined.

The overall quality of your film or sheet decisively depends on the quality of your die. Due to the constant load with high temperatures and the most diversified materials and mechanical cleaning processes, there is always soiling or wear despite the highest production quality.

You can sustainably secure the quality of your production only with a professional and timely revision of your film or sheet die. BREYER Services offers you a sustainable solution.

YOUR ADVANTAGES

- Perfect and sustainable revision of your die

- Sustainably high quality of your film and sheet

- Production security

Our services

- Opening and cleaning of the die

- Repair of damages in the die body and lip area

- Replacement of defective parts

- CNC-supported and manual fine polishing

- New chrome-plating of the die

- Final assembly and heat up of the die

BREYER calender roll cleaning

– your guarantee for sustainable quality and economic efficiency.

The BREYER calender rolls ensure the perfect surface of your film and sheet and excellent thickness tolerance. The efficient cooling of the plastic melt on the roll surface enables the high output of your extrusion line.

Due to variations in cooling water qualities in combination with the appropriate cooling water temperatures, the soiling of the cooling water channels is possible from time to time despite the high production quality. This leads to a reduction of the cooling performance and thus a lower output of your extrusion line. Possible scratches in the roll surface caused by production and roll cleaning additionally reduce your sheet and film quality.

You can ensure the economic efficiency and quality of your production only with a professional and timely revision of your calender rolls. BREYER Services offers you the perfect solution.

YOUR ADVANTAGES

- Practically new calender roll

- Sustainable high quality of your film and sheet

- Economic efficiency of your production

- Failure protection for your production