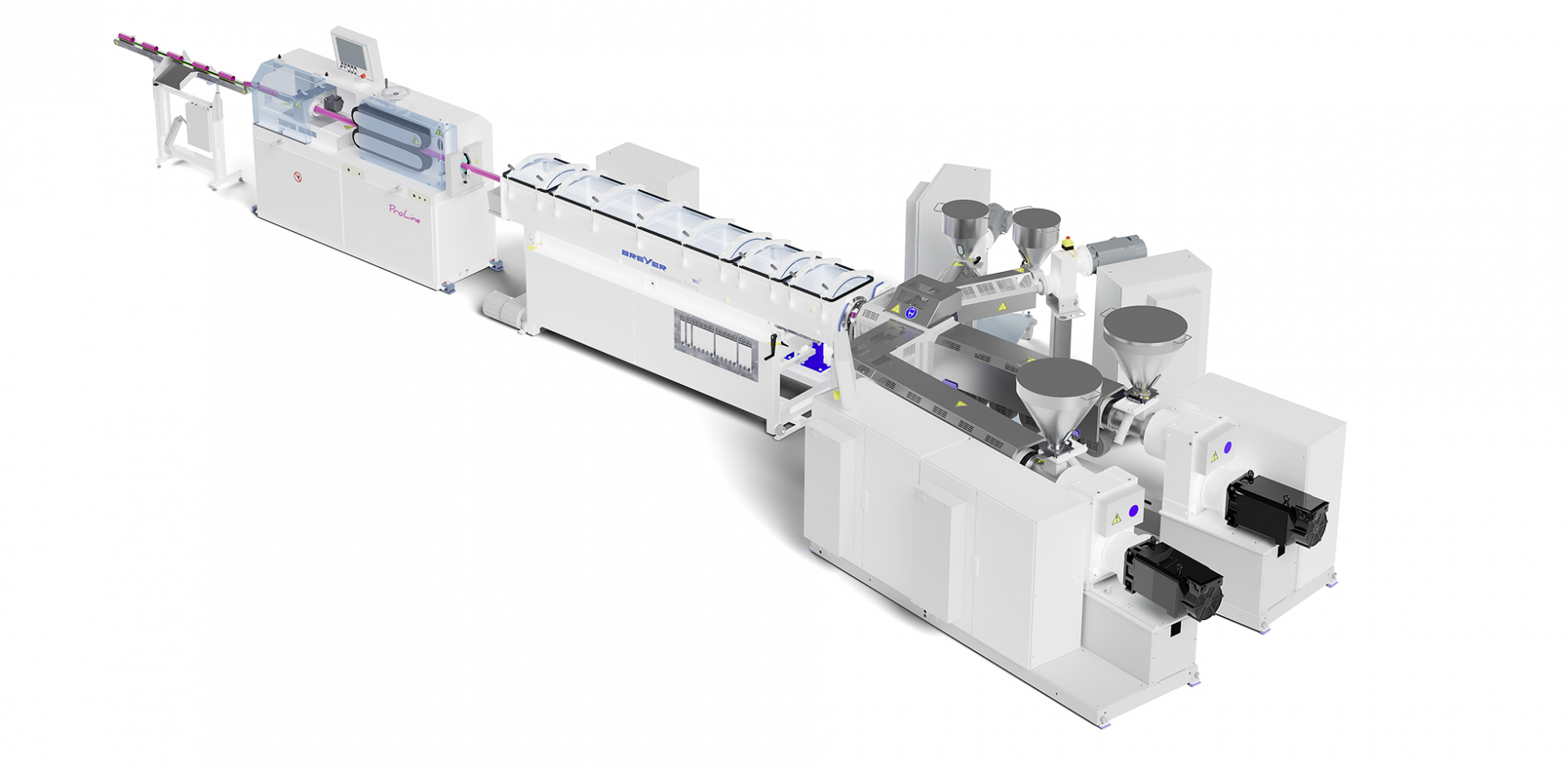

BREYER ProLine

Extrusion lines for tubes

Produce professional tubes even more economically

When it comes to tube packaging for the cosmetics industry, perfection and a professional design are paramount. However, packaging must also be manufactured economically.

Stay ahead of your competition.

Today, speed is a top priority in many production processes. It‘s good if you can refer to a technology that delivers good quality even at high speeds.

Clients from the world of cosmetics, which has high standards, know to appreciate this fact because perfect looks and tactile qualities often decide the success or failure of a product. Still, economic efficiency cannot be neglected in the production process. The BREYER ProLine meets with both standards in an optimal way – especially when the decision is made in favor of a multi-layer design.

The intelligent way to save energy and cost: please click here

Advantages

- Cutting capacities up to 200 tubes/min., resp.34m/min

- Fast start-up within minutes.

- Fast tool exchange for different tube diameter.

- Short time for colour and material change.

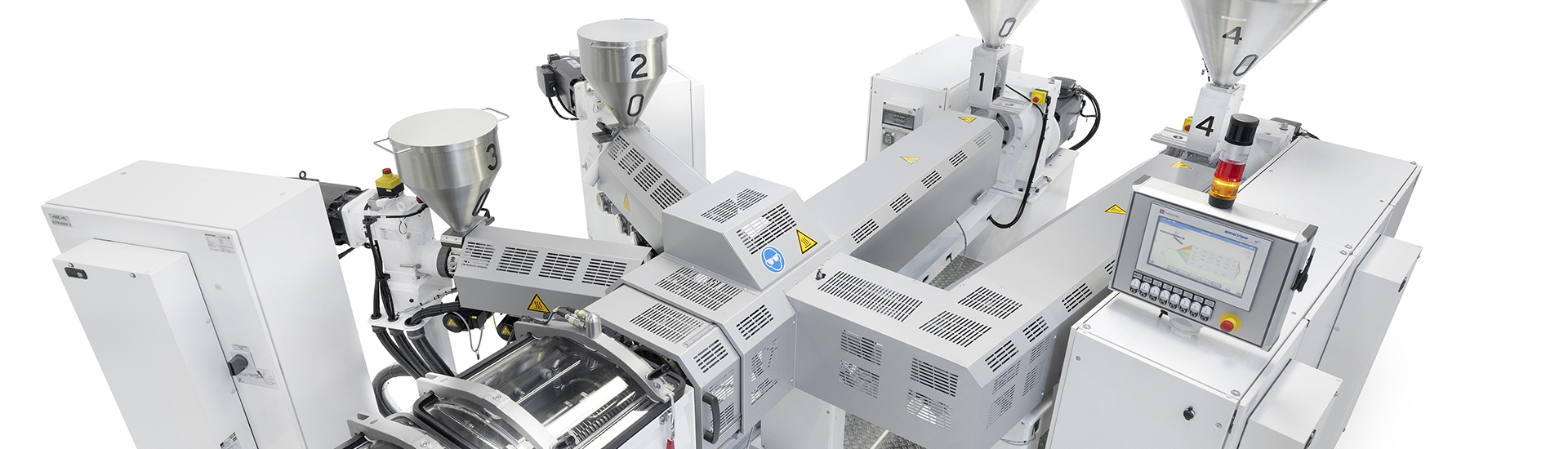

- Modular design – integration in complete lines.

- Proofed BREYER tube extrusion technology.

Technical data

| Tube diameter: | 13 – 60 mm |

| Length: |

39 – 300 mm |

| Performance: |

– 200 tubes/min |

| Materials: |

LDPE, LLDPE, MDPE, HDPE, CoPP, Mixtures |

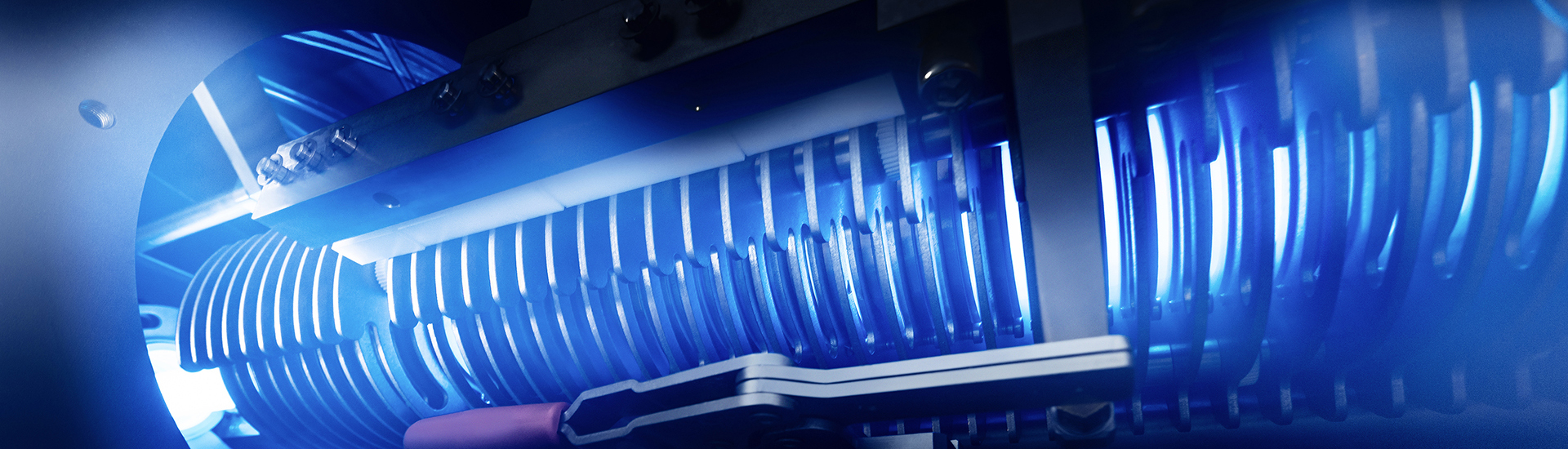

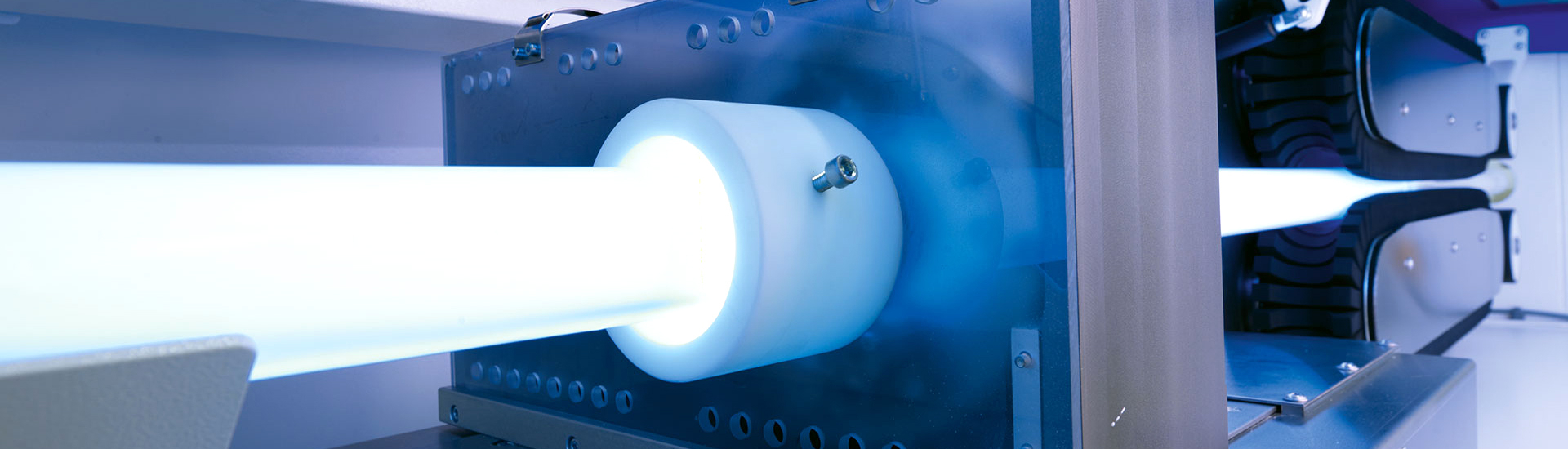

| Variations: | Mono und Co-Extrusion (up to 5 layers) |

Examples of application