BREYER IONDry

The Future of Electrode Production

BREYER develops new calender system for electrode production by dry process.

We are working on the development of processes that enable the processing of dry and ideally solvent-free battery compounds into a flowable film.

BREYER IONDry - future technology today

In parallel with the BREYER IONPress compaction technology for so-called wet-coated cells, BREYER has also been working since 2009 on the development of dry processing, which enables the processing of dry and ideally solvent-free battery compounds into a flowable film.

Two processes have been further developed at BREYER in recent years: The first is the extrusion process, in which the dry masses are processed into a flowable film using an extruder and a wide slot die.

In the second process, BREYER IONDry, a film is first produced in several process steps, its thickness is adjusted, and in the final step it is laminated onto the conductor. What is special here is that all three process steps take place within one machine, but each process step is individually accounted for by the roller arrangement and individual pressing forces.

Years of expertise in calender roll development and gap control technology now give operators a competitive edge in electrode manufacturing thanks to the future-oriented BREYER IONDry system.

For their own further development, BREYER offers innovative processors the BREYER IONDry 400 core laboratory and development system on a laboratory scale.

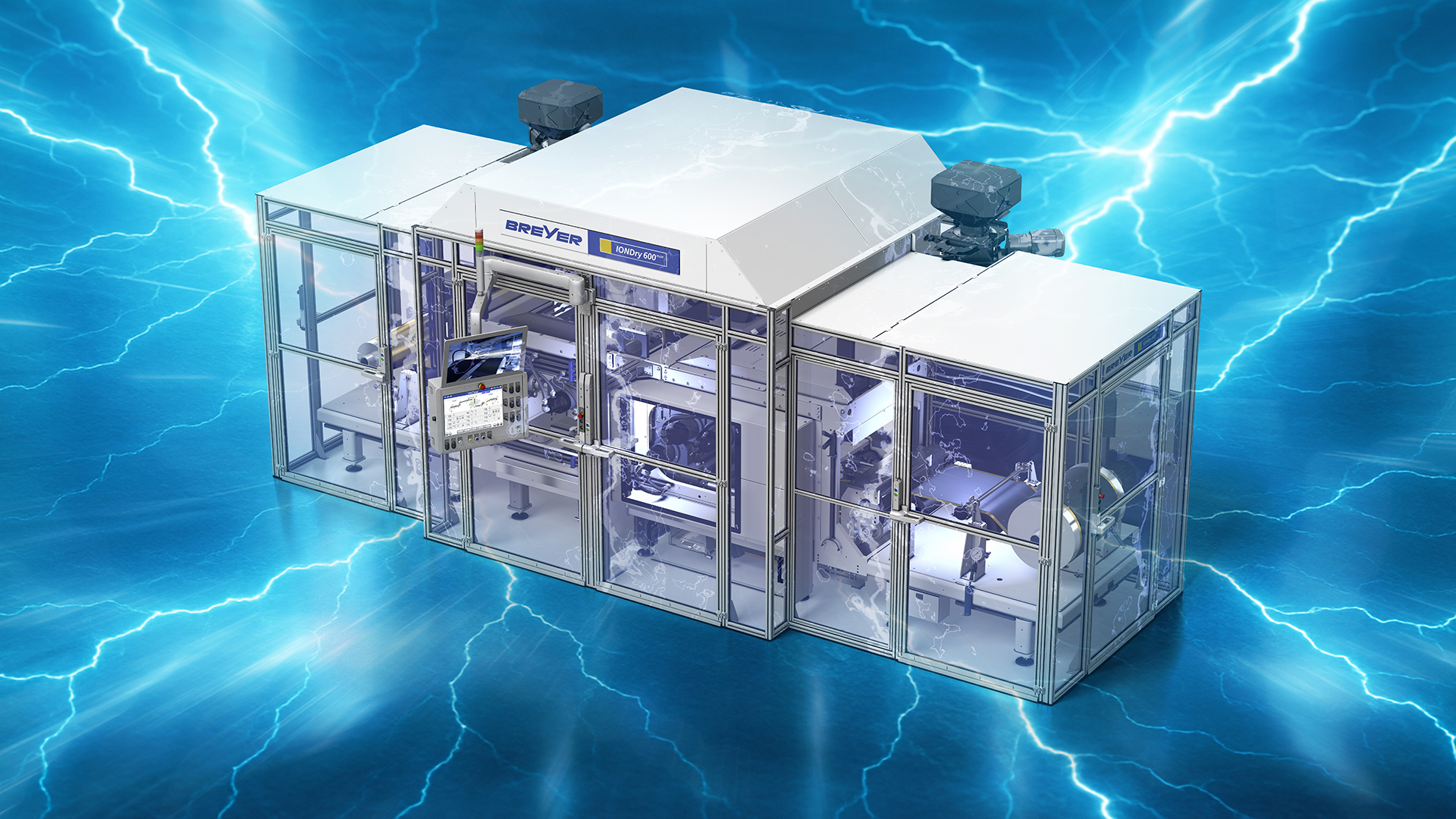

The IONDry 600 pilot is a pilot line and ideal for upscaling tasks or initial production runs.

New approaches in electrode production – the process

The aim of the development is to reduce the production costs for battery cells and establish a more environmentally friendly alternative to conventional wet coating. In contrast to conventional electrode production, this process involves dry mixing the raw materials without solvents. An electrode web is then produced from the dry premix in the roll gap and applied to the current conductor foil (aluminum or copper).

The IONDry 600 pilot calender enables the premixed dry material to be continuously fed into the roll gap and a continuous conductor web to be coated on both sides. The material is then wound up. A newly developed dosing system, which is linked to the calender, ensures automatic feeding and controlled distribution of the powdered material as well as its precise feeding into the roll gap.

The rotating rolls create a homogeneous film, the thickness of which can be precisely adjusted depending on the roll speed. The roll gap itself can be precisely regulated via an electrohydraulic system. The system has several precise and controlled roll gaps, so that two films for the top and bottom of the electrode can be produced simultaneously and then laminated onto the conductor to form a composite.

BREYER · Innovations for better Solutions

Please contact us and ask us about BREYER IONDry and BREYER IONPress. The future has begun – with BREYER energy solutions you will also be one step ahead.

Advantages

Technological highlights of the IONDry 600 pilot line

■ Solvent-free process – No chemical solvents are used, ensuring environmentally friendly and resource-efficient production.

■ Lower operating costs – No energy-intensive drying is required, reducing energy consumption and production costs.

■ Automated conveyor system, synchronized with the calender

■ Precise gap control – The newly developed control system enables force- and distance-adjustable gap settings for maximum coating accuracy.

■ Inline sensors for process control – Integrated sensors enable continuous monitoring and optimization of the coating process.

Dry coating technology represents a groundbreaking alternative to conventional wet coating, as it not only reduces environmental impact but also significantly lowers investment and operating costs.

With the development of the IONDry 600 pilot, BREYER has set an important milestone in the development of sustainable production processes for battery cells.

Examples of application