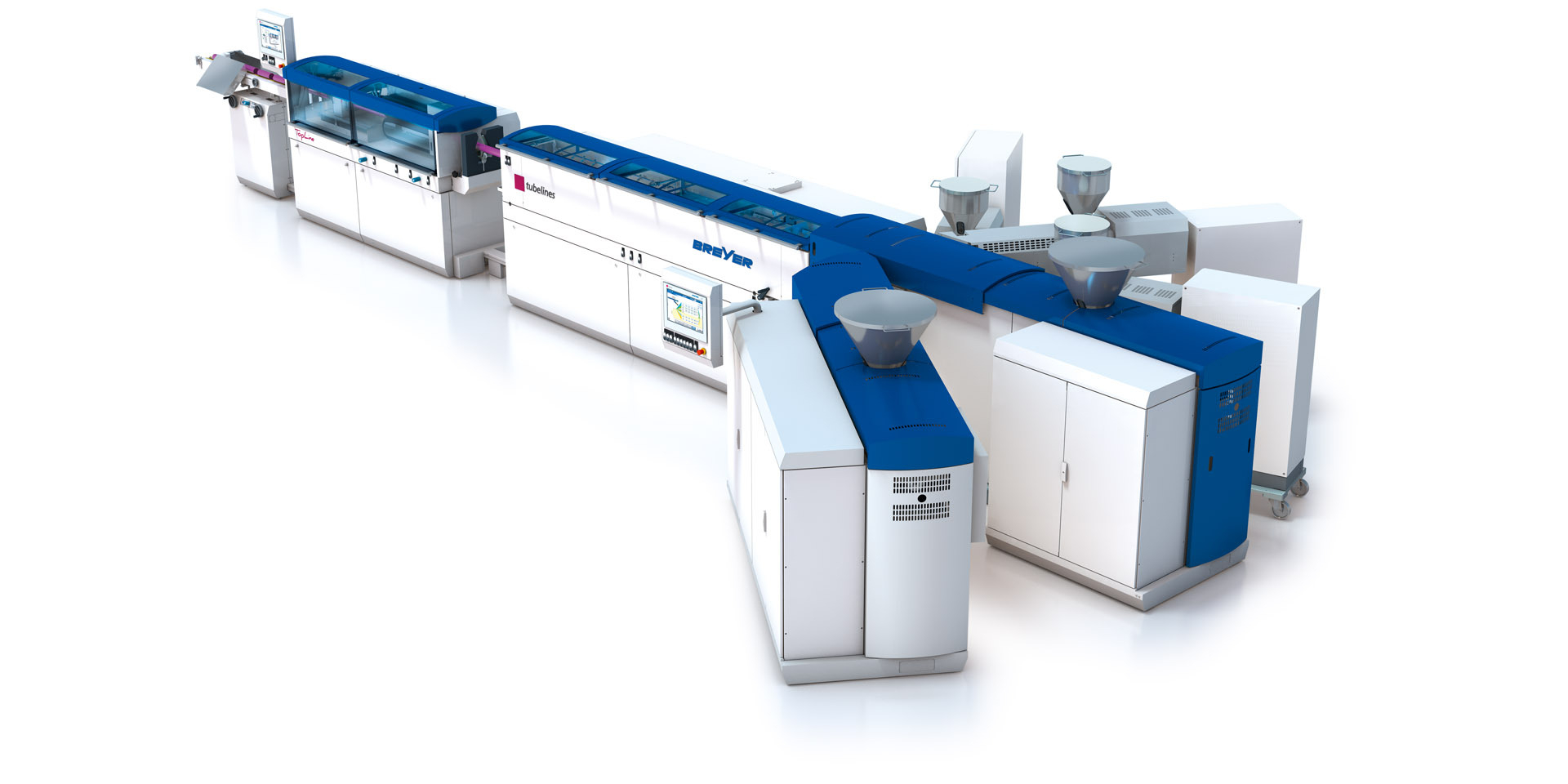

BREYER TopLine extruder

The BREYER TopLine Extruder - ahead right from the start.

BREYER has managed to develop something, which many customers desire: one screw for processsing many different materials - allowing customers to be in the lead over their competitors.

New, Clear Design

New aesthetics that match the tube products

Intelligent Energy Management

for saving up to 20% in energy costs

- Gearless direct drives / water cooled torque drives

- Fan units with flaps

- Heat insulation for cylinder and die head

- Slow-down and standby function

- Peak reduction

Noise reduction

of approx. 11 dB (A)

Process Data Recording

Monitoring and controlling the adjustment parameters and production data, ideal recipe management and considerably higher repeatability of production data resp. product qualities.

New Operating Panel · Interface

- Clear and user-friendly software organized in various steps/levels

- Different level steps

- Recipe management

- Quality management

- Service page · teleservice

- Modular setting

BREYER TopLine

Extrusion line for the production of tube sleeves

Today, speed and quality are top priority in many production processes. It's good if you can refer to a technology that delivers good quality even at high speeds. Clients from the world of cosmetics, which has high standards, know to appreciate this fact.