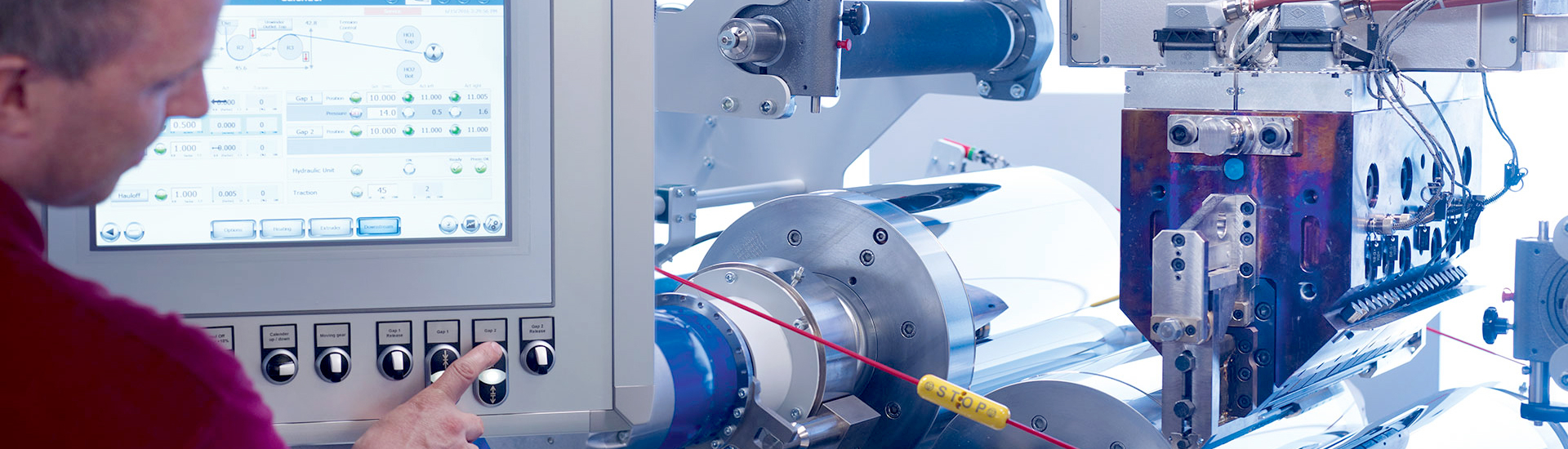

Extrusion line BREYER TubeFlex

The flexible way to produce tube laminate film.

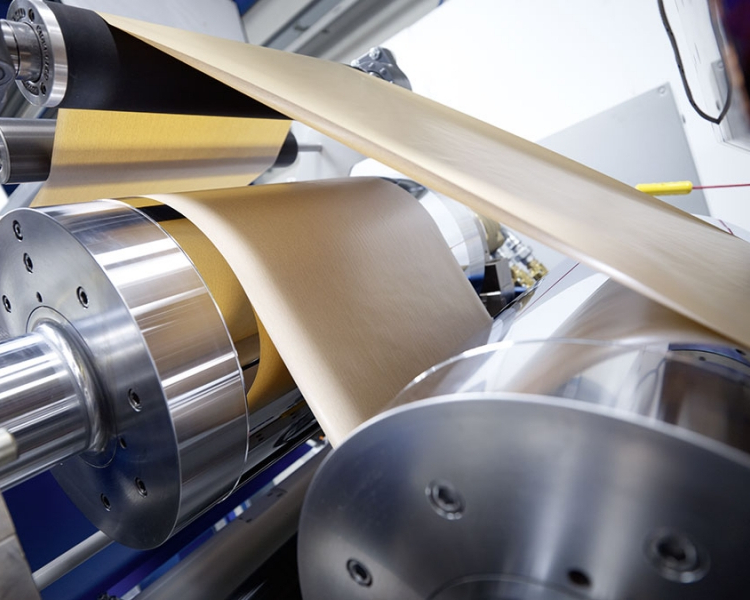

Extrusion line for the production of high-quality laminate film

With the BREYER TubeFlex system, colors, materials, layer thicknesses and additional decors can be combined into a flat film in a highly flexible way.

There are almost no limits on your imagination for tube design. Produce your individual tube design and fascinate your customers.

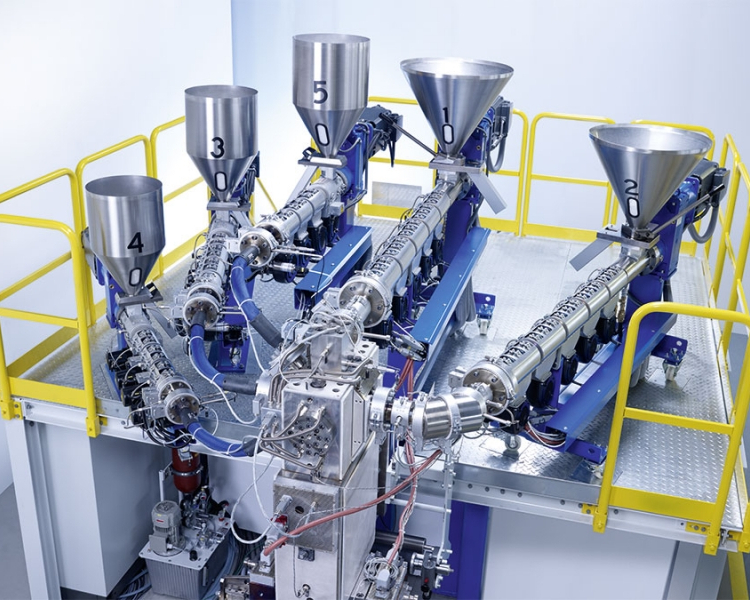

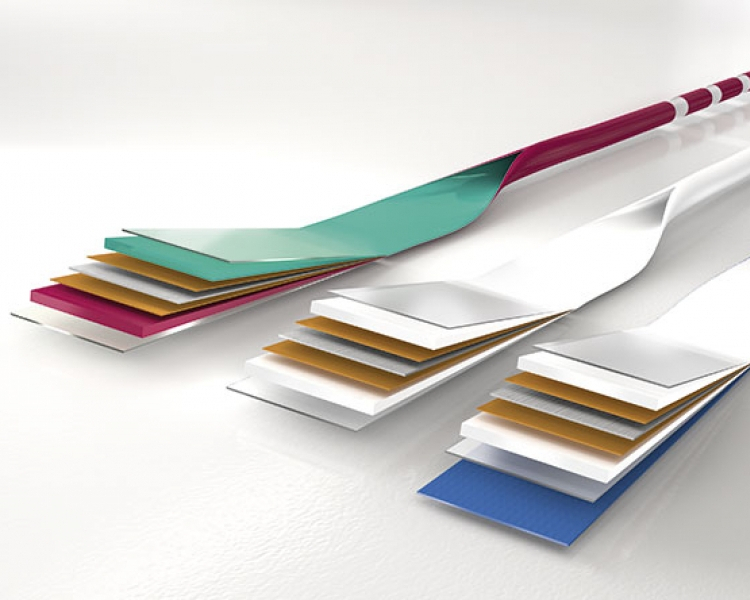

Multi-layer film structure

Number of layers: 7

Features: Adjustable distribution during operation via rotary elements, specific edge encapsulation

Applications: Multilayer polyolefin films with EVOH barrier and adhesive layer

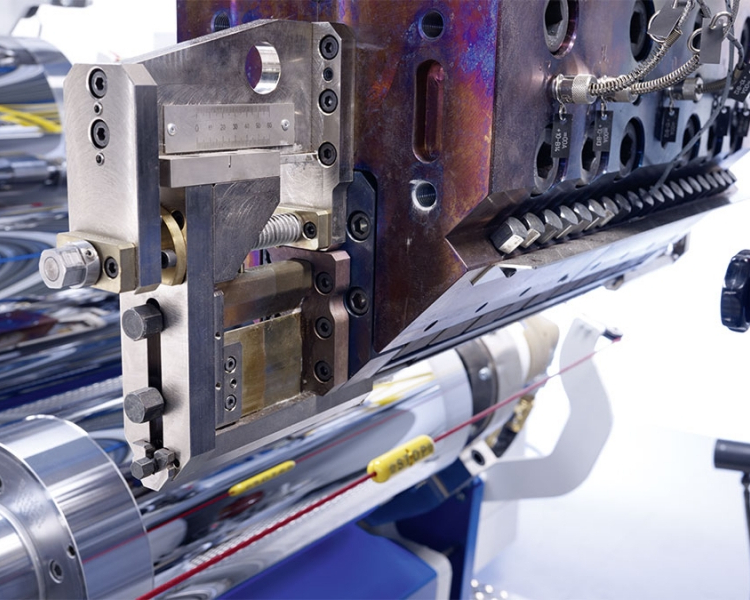

Multi-layer feedblock with adjustable profiled rotating elements to adjust the distribution of each layer. Specially optimized for the production of barrier films with high demands on the layer thickness distribution. Customization of the edge encapsulation can take place via the internal replaceable edge encapsulation insert.

BREYER TubeFlex extrusion lines for the production of tubes for:

- Body care products

- Hair care products

- Sunscreen

- Toothpaste

- Detergents

- Technical products

- Glues

- Food

优势

- Development of new markets

- Product innovations

- Custom-tailored film composition

- Increased added value through in-house production

- Small batch sizes

- Broad range of materials

- Diversified, individual designs

技术资料

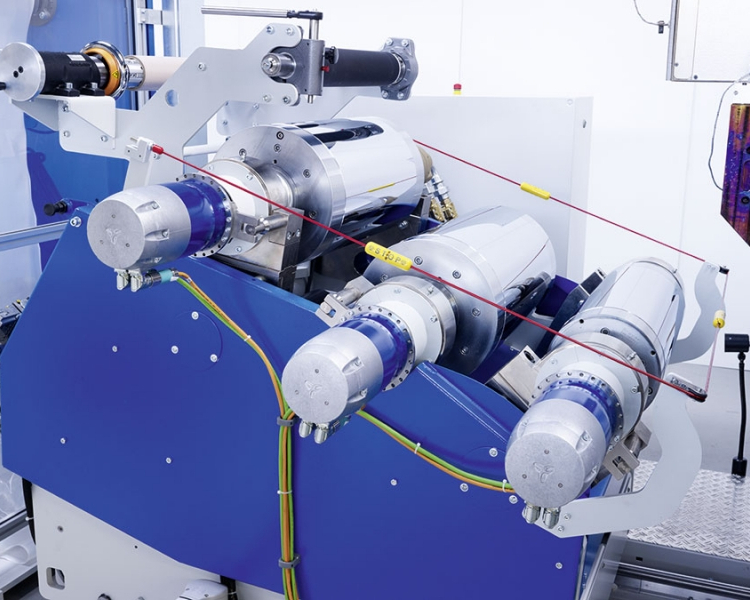

| Film widths: up to 400 mm,net* | |

| Film thicknesses: 250 – 500 μm | |

| Materials: LDPE, HDPE, mixtures, barrier, bonding agent | |

| Number of layers: up to 7* | |

| Decors: single-sided (inside or outside) | |

| * further on request |

应用的领域

组成部分

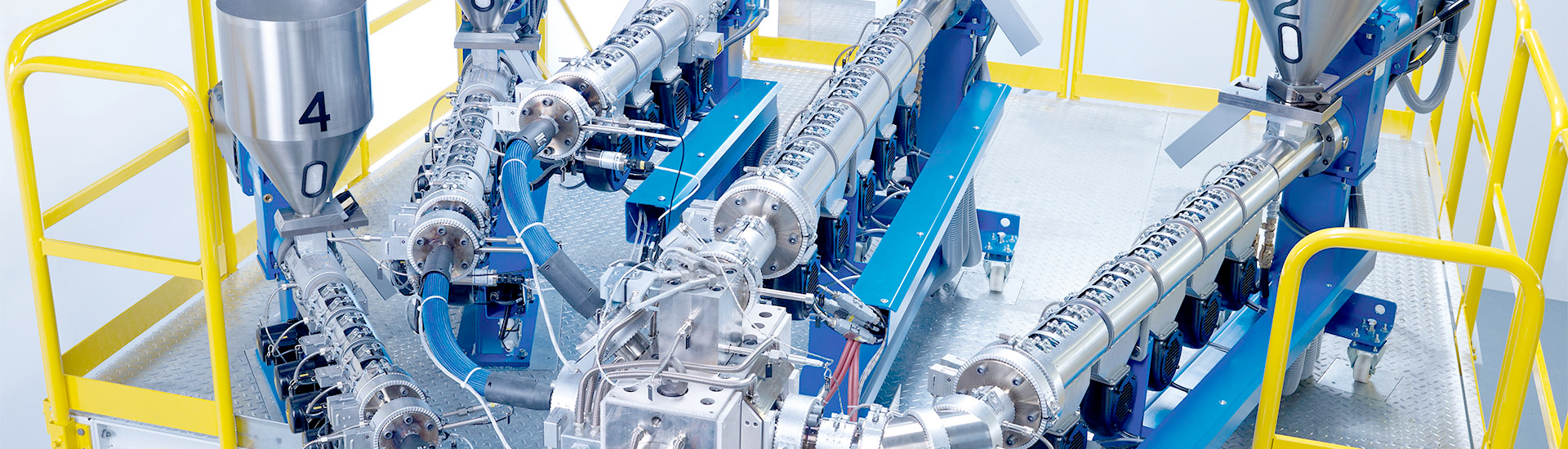

多层共挤

单层模头配备多层共挤分配器后,可使多层结构更快也更容易生产及调整,进而生产出更复杂的多层光学薄膜和板材产品。